The automatic trackless transfer cart, also known as an AGV transfer cart, is an intelligent heavy-duty material handling device based on AGV technology. This 8-tonne lifting capacity AGV cart manufactured by REMARKABLE employs a laser navigation system, eliminating the need for track or magnetic strip installation to achieve autonomous navigation, path planning, and precise positioning. It supports multi-directional movement and high-precision docking, featuring a platform lifting function that enables flexible integration with production lines and workstations. Widely deployed in smart factories, heavy manufacturing, and automated production lines.

REMARQUABLE offre des services de personnalisation couvrant la capacité de charge, la conception de la plate-forme, les modes de contrôle et les modules fonctionnels afin de répondre aux diverses exigences opérationnelles.

- Capacité de charge : 8 Tons

- Dimensions : 3500 × 1700 × 400 mm

- Course de levage : Hydraulic lifting, 100 mm

- Alimentation électrique : Lithium iron phosphate battery

- Vitesse : 0–25 m/min (stepless speed regulation)

- Sur mesure : Possibilité de production sur mesure, y compris des composants supplémentaires, etc.

Working Principle of the Automatic Trackless Transfer Cart

This automatic trackless transfer cart employs a laser SLAM navigation system for operation. Through continuous scanning and mapping of the surrounding environment, it achieves real-time positioning and autonomous path planning. Furthermore, it automatically completes material handling tasks according to dispatch system instructions or manual commands, eliminating the need for human operation.

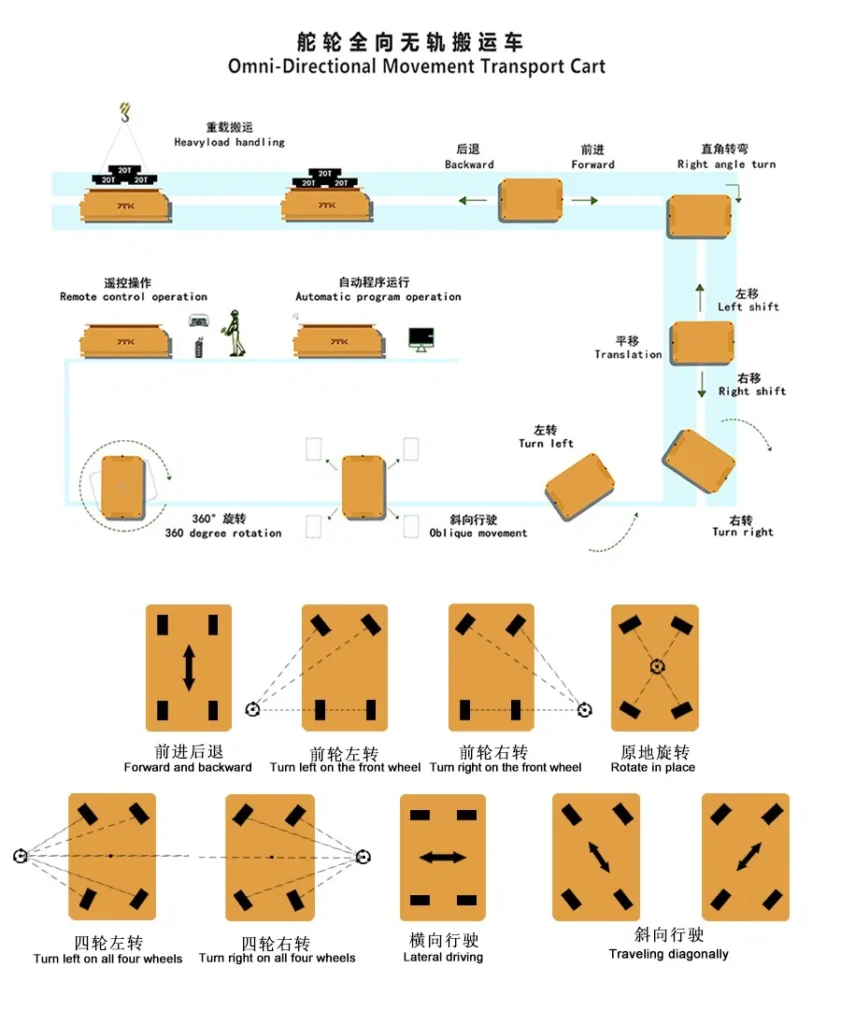

During operation, the transfer cart supports multiple movement modes, including forward, lateral, diagonal movement, and in-place rotation, flexibly adapting to complex factory layouts. When approaching target workstations, it achieves high-precision docking with ±20mm accuracy. Moreover, the full-surface hydraulic lifting mechanism permits fine height adjustment, ensuring smooth alignment between materials and production lines or equipment. Simultaneously, the laser obstacle avoidance system and multiple safety protection devices continuously monitor the operational environment, guaranteeing reliable and secure equipment operation.

Chariot de transfert automatique sans rail

The Automatic Trackless Transfer Cart Function

This heavy-duty 8-tonne automatic trackless transfer cart features highly integrated functional modules, designed for high-load, continuous operation scenarios to enhance long-term operational stability.

- Traverse and Steering System

Employing a composite traverse structure comprising four steering wheels and four swivel castors, it achieves omnidirectional movement, including forward, reverse, lateral, diagonal shifts, and on-the-spot rotation. This enables agile operation within narrow passages, intersections, and complex factory environments. - Drive and Power System

Features an independent multi-motor drive for stable, reliable power output, safely handling 8-tonne loads while maintaining smooth operation. Suited for high-frequency, prolonged continuous operation, effectively enhancing overall operational efficiency and service life. - Navigation and Control System

Equipped with a laser SLAM trackless navigation system, eliminating fixed routes by enabling autonomous mapping and path planning. Additionally, it supports multiple control methods, including autonomous operation, wireless remote control, and industrial tablet interfaces, facilitating seamless integration with automated systems. - Lifting System

Features a full-surface hydraulic lifting mechanism with smooth, synchronised movement. Enables precise height adjustment at workstations, ensuring safety and stability during material transfer and docking operations. Ideal for accurate height alignment with production lines, automated equipment, and workstations. - Safety Protection System

Integrated with laser obstacle avoidance, emergency stop buttons, safety edge sensors, and audible/visual alarms, it provides real-time monitoring of operational zones. Multi-layered safeguards prevent collision risks, ensuring personnel and equipment safety during operation.

Chariot de transfert automatique sans rail

Spécifications techniques Vue d'ensemble

Explore the technical specifications of this 8-tonne automatic trackless transfer cart. Featuring 270-degree mobility and hydraulic lifting capabilities, it enables safe and precise operation.

| Type | Paramètres | Remarks |

|---|---|---|

| Equipment Name | AGV-8t | 8-ton automatic trackless transfer cart |

| Rated Load (t) | 8 | |

| Platform Size (mm) | 3500 × 1700 | |

| Platform Height (mm) | 400 | |

| Vitesse de déplacement (m/min) | 0–25 | Vitesse réglable |

| Motor Power | 4 × 2 kW | |

| Alimentation électrique | Lithium Iron Phosphate Battery | |

| Operating Time | Approx. 4 h | |

| Charging Time | ≤ 4 h | |

| Braking Mode | Electromagnetic Braking | Power-off brake |

| Wheel Configuration | 4 Steering Wheels + 4 Caster Wheels | |

| Matériau de la roue | Polyurethane Coated Wheels | |

| Motion Modes | Forward, Backward, Lateral, Longitudinal, Diagonal, In-place Rotation | |

| Navigation Method | Laser SLAM Navigation | |

| Control Mode | Automatic Operation Wireless Remote / Wired Control Handle Industrial Tablet | |

| Platform Lifting | Full Platform Lifting | |

| Lifting Height (mm) | 100 | |

| Lifting Type | Hydraulic | |

| Protection de la sécurité | Laser Obstacle Avoidance | 270° front and rear |

| Protection de la sécurité | Audible & Visual Alarm Light | |

| Protection de la sécurité | Emergency Stop Button | |

| Protection de la sécurité | Safety Edge | |

| Body Color | Yellow | Personnalisable |

| Positioning Accuracy | ±20 mm |

These are some of the specifications for our AGV transfer cart. If you are interested in our intelligent AGV cart, please contact us, and we will provide customised services tailored to your requirements.

Vidéos Show

Custom Series Parameters for Automatic Trackless Transfer Cart

| Tableau des paramètres techniques du chariot de transfert électrique sans rail RWP | |||||||||||

| Capacité de charge nominale(t) | 5 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | |

| Taille du tableau (mm) | Longueur | 2400 | 2700 | 2700 | 3000 | 3500 | 4000 | 4500 | 5000 | 6000 | 6000 |

| Largeur | 1500 | 1800 | 1800 | 2000 | 2200 | 2000 | 2200 | 2500 | 3000 | 3000 | |

| Hauteur | 470 | 550 | 600 | 700 | 700 | 800 | 900 | 1000 | 1000 | 1000 | |

| Garde au sol(mm) | ≥50 | ≥100 | |||||||||

| Rayon de braquage(mm) | 2200 | 2500 | 2500 | 2800 | 3300 | 6000 | 6800 | 7500 | 9000 | 9000 | |

| Mode de pilotage | Direction différentielle | Direction hydraulique | |||||||||

| Méthode de fonctionnement | Télécommande et pendentif manuel | ||||||||||

| Bougez ! | Forward, backwards, turning while driving with no stop | Temperature: -10°c~40°c; Humidity: 20%~80%, No Condensation (Customised for high-temperature and explosion-proof environments) | |||||||||

| Vitesse de course(m/min) | 25 | 20 | |||||||||

| Type de moteur | Moteur à courant alternatif (CA) à basse tension / moteur à courant continu sans balais (CC) | ||||||||||

| Mode de freinage | Frein électromagnétique | ||||||||||

| Mesures de protection | Voyant d'alarme sonore et visuel+ Bouton d'arrêt d'urgence+Capteur laser d'évitement d'obstacle (en option)+Bord de contact anticollision (en option) | ||||||||||

| Quantité de roues | 4 | 6 | 8 | ||||||||

| Diamètre de la roue motrice(mm) | Ф360 | Ф400 | Ф400 | Ф450 | Ф500 | Ф500 | Ф600 | Ф550 | Ф550 | ||

| Matériau de la roue | Noyau d'acier + polyuréthane | ||||||||||

| Capacité de la batterie(kW-h) | 5.5 | 8.5 | 10.5 | 14 | 18.5 | 18.5 | 30 | 37.8 | 45.3 | ||

| Type de batterie | Batterie plomb-acide | Pile au lithium | |||||||||

| Autonomie de la batterie | 5h (sur mesure) | 4h (sur mesure) | |||||||||

| Temps de charge de la batterie | ≤7h | ≤5h | |||||||||

| Chargeur de batterie | AC220V/AC380V | ||||||||||

| Type de sol | Sol en ciment、Sol en tôle d'acier 、Sol en époxy, sol en asphalte | ||||||||||

| Capacité d'escalade à pleine charge | 5% | 3% | |||||||||

| Environnement de travail | Battery Power Display, Over Voltage, Under Voltage, Over Current Protection, etc | ||||||||||

| Couleur de la carrosserie du véhicule | Sur mesure | ||||||||||

| Autres fonctions | Notes : 1) Other table sizes and load capacities can be customised according to user requirements. 2) Pour la direction hydraulique, un système de direction hydraulique double peut être sélectionné pour réduire le rayon de braquage en fonction des contraintes d'espace du site. 3) Le type de batterie et la durée de fonctionnement (endurance de la batterie) peuvent être personnalisés pour répondre aux besoins des clients. 4)Le produit fait l'objet d'améliorations et de mises à jour constantes ; les spécifications figurant dans le tableau peuvent être modifiées sans préavis. | ||||||||||

| Notes : 1) Other table sizes and load capacities can be customised according to user requirements. 2) Pour la direction hydraulique, un système de direction hydraulique double peut être sélectionné pour réduire le rayon de braquage en fonction des contraintes d'espace du site. 3) Battery type and operating time (battery endurance) can be customised to meet customer needs. 4)Le produit fait l'objet d'améliorations et de mises à jour constantes ; les spécifications figurant dans le tableau peuvent être modifiées sans préavis. | |||||||||||

Features of Automatic Trackless Transfer Cart

Trackless Autonomous Operation

Utilises laser SLAM navigation, eliminating the need for track installation to enable flexible deployment and autonomous movement.

Capacité de charge élevée

Rated load capacity of 8 tonnes with robust construction, suitable for handling heavy components and equipment.

Omnidirectional Mobility

Supports forward, lateral, diagonal movement and in-place rotation, adapting to complex factory pathways.

High-Precision Docking

Utilises SLAM technology for positioning and docking accuracy of ±20mm, meeting production line interface requirements.

Full-Platform Hydraulic Lifting

Synchronised platform elevation facilitates precise integration with workstations and automated equipment.

Protection de la sécurité

Integrated laser obstacle avoidance, emergency stop, and audible/visual alarms provide comprehensive operational safeguards.

Application of Automatic Trackless Transfer Cart

The 8-tonne lift automatic trackless transfer cart finds extensive application across manufacturing, warehousing, and logistics sectors. This AGV enhances safety and efficiency, fulfilling diverse material handling requirements with flexibility and reliability.

Manufacturing production lines: Suitable for the automated transfer of raw materials, semi-finished products and tooling between different workstations, reducing manual handling and enhancing production efficiency.

Heavy industry and equipment manufacturing: Frequently employed for trackless handling of large structural components, heavy machinery and oversized workpieces, enabling safe and efficient transfer under complex operating conditions.

New Energy and Power Industry: Suitable for transporting high-value materials such as battery modules and electrical equipment, ensuring safety and stability throughout production and assembly processes.

Automotive and Component Manufacturing: Ideal for the automated transfer of engines, moulds, and body components, enhancing production line flexibility and overall automation levels.

Smart Warehousing and Logistics: Primarily employed for material transfer between storage and production zones, enabling automated scheduling and precise distribution to boost logistics operational efficiency.

Chariot de transfert Vitrine

Automatic Trackless Transfer Cart Manufacturer

Henan REMARKABLE Intelligent Technology Co., Ltd. is a specialist manufacturer dedicated to the research, development, design, production, sales, and after-sales service of industrial transfer carts and AGV transfer carts. The company manufactures handling equipment and accessories across various tonnage capacities, while also providing professional R&D, design, and manufacturing services for customised electric transfer carts, rail-guided trolleys, omnidirectional mobile transfer carts, trackless transfer carts, AGV robotset remorques industrielles.

The REMARKABLE possesses a comprehensive production system, stringent quality management, and extensive industry experience. Its products comply with the JB/T6127-2010 machinery industry standard, have passed the ISO three-system certification (quality, environment, and occupational health), and the CE certification. It has obtained 19 national product patents successively.

Pourquoi nous choisir ?

- Expertise sectorielle - Nous proposons aux secteurs de la production d'énergie, de la construction navale, de la construction et de l'aérospatiale des solutions sur mesure pour les transformateurs, les composants d'éoliennes, les modules préfabriqués, etc.

- Fully Customised - De la capacité de charge (1-500+ tonnes) aux systèmes d'entraînement (électrique, hybride ou diesel), nous répondons à vos besoins exacts.

- Systèmes de contrôle avancés - Les options comprennent la commande manuelle à distance, la planification semi-automatique du trajet ou la navigation entièrement automatisée (intégration d'un AGV).

- Qualité et durabilité - Cadres en acier robustes, modules de direction à couple élevé, certifiés CE et ISO.

- Soutien complet au projet - De la consultation initiale au service après-vente, nos ingénieurs fournissent une assistance technique à vie.

Articles connexes

Solutions personnalisées de manutention intelligente

Pour qu'un chariot de transfert personnalisé corresponde parfaitement à vos besoins, veuillez fournir les informations suivantes :

- Capacité de charge : _____ tonnes (1~500 tonnes)

- Taille du tableau : _____ × _____ mm/m (par exemple, 1500×3000)

- Options d'alimentation :

- ☐ Plomb-acide ☐ Lithium-ion ☐ Autre : _____

- ☐ Câble : _____V/_____A

- ☐ Standard 380V/50Hz/3-phases

- Détails de la cargaison :

- Type : _____ (par exemple, bobines d'acier, machines)

- Besoins particuliers : _____ (par exemple, antidérapant, résistant à la corrosion)

- Caractéristiques optionnelles :

- ☐ Arrêt d'urgence ☐ Capteurs anti-collision

- ☐ Guides de rail ☐ Mécanisme de levage ☐ Télécommande