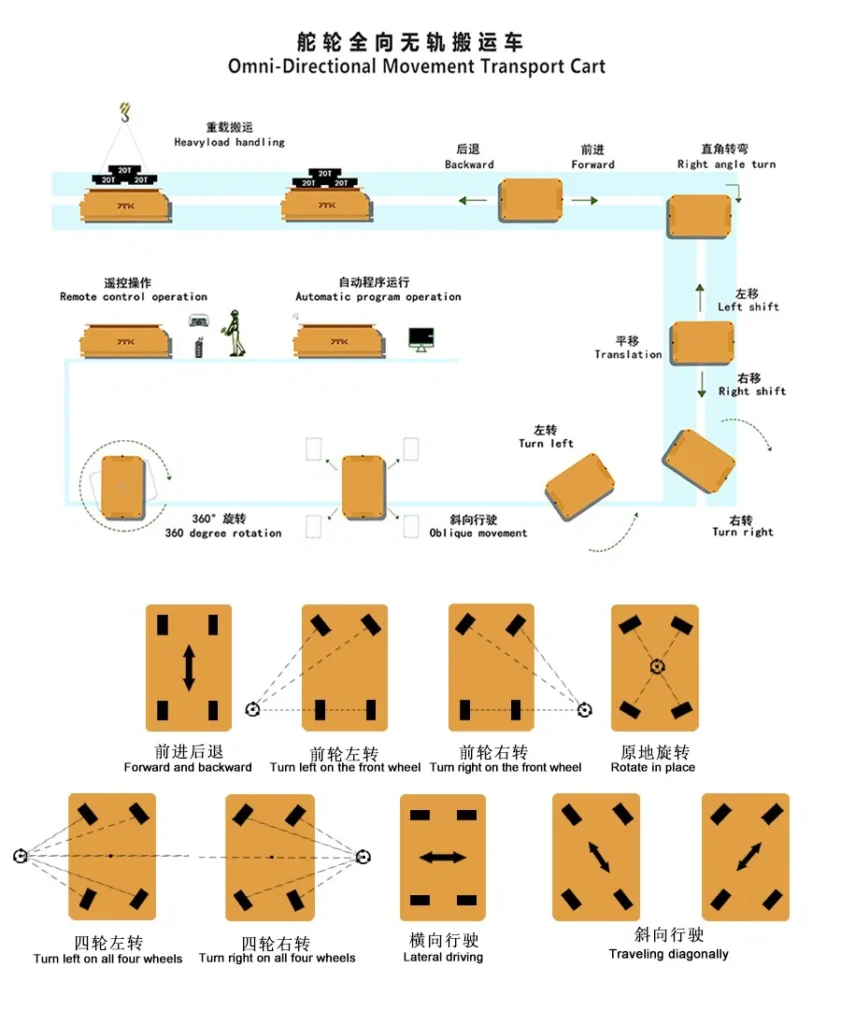

العربة المتحركة متعددة الاتجاهات هي عبارة عن روبوت متحرك متخصص أو جهاز مناولة المواد، وتتمثل ميزته الأساسية في القدرة على التحرك في أي اتجاه. وبعبارات بسيطة، لا يمكنها التحرك للأمام والخلف فحسب، بل يمكنها أيضًا التحرك إلى الأمام والخلف، وكذلك الدوران بزاوية 360 درجة في مكانها. وقد عالج إدخالها بشكل كبير مشكلة المناورة في مساحات المصانع الضيقة، كما أن الأنواع المختلفة المخصصة من العربات المتحركة متعددة الاتجاهات قد حلت أيضًا تحديات مناولة المواد في مختلف ظروف العمل ومستويات التعقيد.

وهي تُستخدم على نطاق واسع في التخزين الذكي والخدمات اللوجستية، والفضاء، وخطوط تجميع السيارات، وروبوتات الخدمة، والأبحاث، والتعليم لمناولة المواد على نطاق واسع ومهام النقل في المساحات الضيقة والمعقدة. والآن بعد أن فهمنا ماهية هذا الجهاز، دعونا نلقي نظرة فاحصة على كيفية عمل العربات متعددة الاتجاهات.

كيف تعمل العربات متعددة الاتجاهات.

تعلمنا مما سبق ما هي العربة المتحركة متعددة الاتجاهات. والآن دعنا نلقي نظرة على كيفية عملها. يمكن تقسيم مبدأ عملها إلى ثلاثة أجزاء: وحدة القيادة AGV المكونة الأساسية، ونظام التحكم، والملحقات المخصصة.

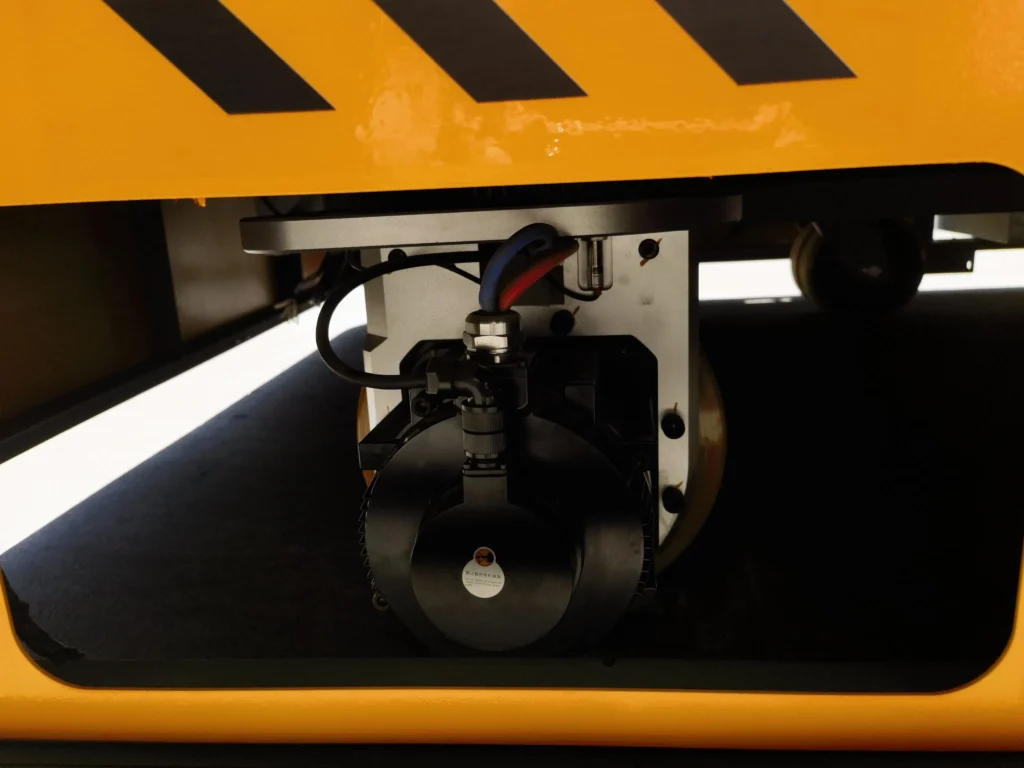

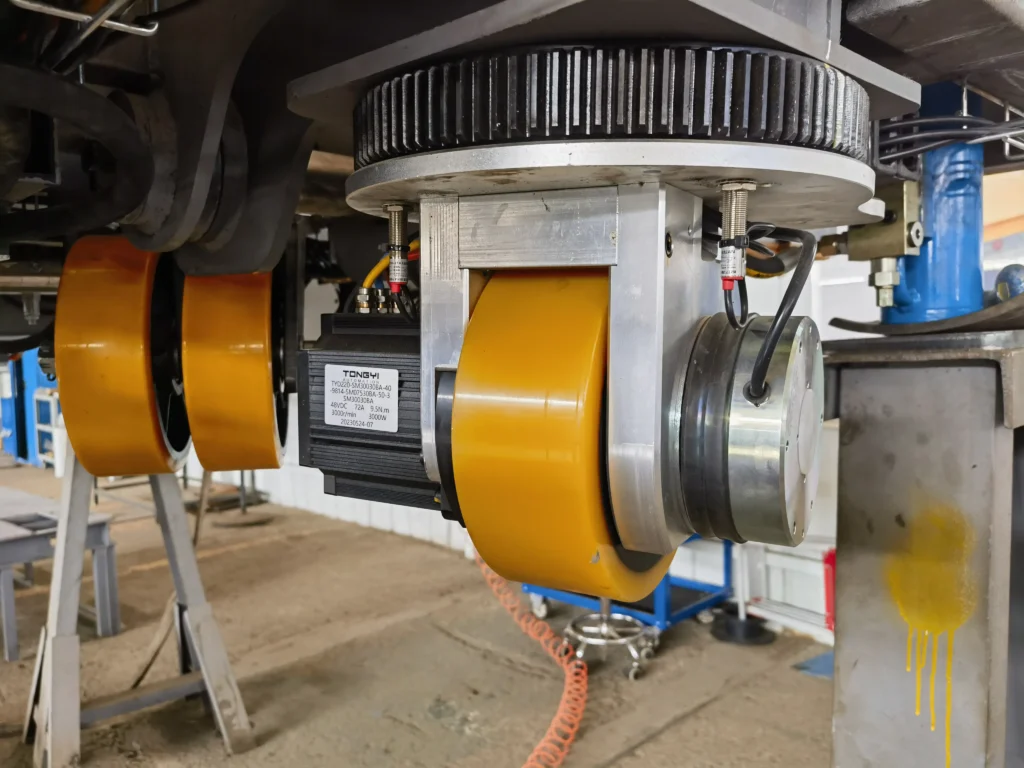

المكوّن الأساسي: وحدة قيادة مركبة نقل AGV

هذا المكوّن هو الخيار الأكثر اقتصاداً وفعالية في الوقت الحالي. وهو يدمج بشكل أساسي محركين: محرك دفع (مسؤول عن تدوير العجلات) ومحرك مؤازر للتوجيه (مسؤول عن تغيير اتجاه العجلات).

مبدأ عملها الأساسي

- يمكن لمحرك مؤازر التوجيه التحكم بدقة في العجلات لتوجيهها في أي زاوية داخل المستوى.

- ثم يتحكم محرك الدفع في العجلات للتحرك إلى الأمام أو الخلف أو التوقف في هذا الاتجاه.

- من خلال تنسيق اتجاه وسرعة جميع وحدات دفع العربة AGV، يمكن توجيه القوى الناتجة عن جميع العجلات نحو نفس الاتجاه، والعمل معًا لتحريك المنصة، وبالتالي تحقيق وظائف مناولة المواد ونقلها لعربة متحركة متعددة الاتجاهات.

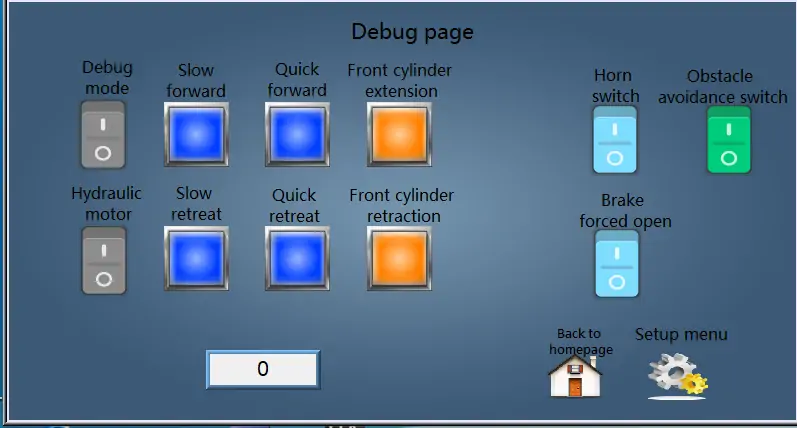

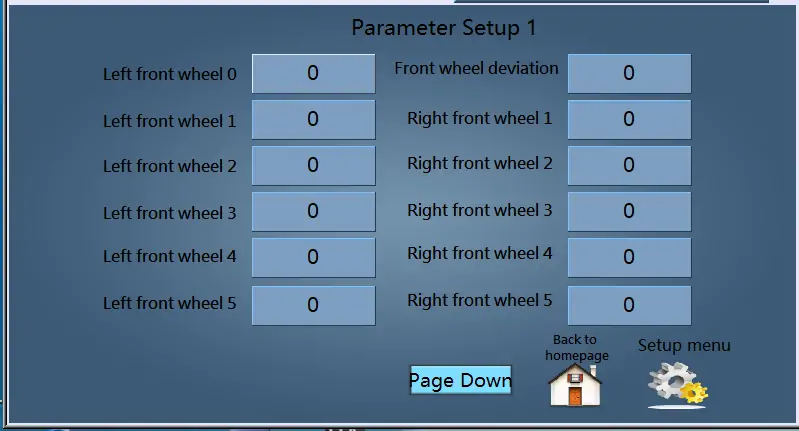

نظام التحكم:

نظرًا لأن كل وحدة قيادة مركبة نقل بمحرك AGV هي نظام مستقل، فإن عدد وحدات قيادة مركبة نقل بمحرك AGV المجهزة في كل عربة نقل متعددة الاتجاهات يختلف حسب الحمولة ونوع البضائع التي يتم نقلها. عادةً ما يكون هناك من 4 إلى 12 وحدة قيادة مركبة نقل AGV، مع إنتاج مخصص بناءً على متطلبات سيناريو العميل.

نظام التحكم عبارة عن كمبيوتر مدمج أو متحكم دقيق عالي الأداء. وتتمثل وظيفته الأساسية في توحيد اتجاه جميع وحدات قيادة العربات ذاتية القيادة. ويصدر الأوامر لها، مما يمكّنها من التعاون وإكمال المهام.

الخطوات:

- أوامر الإدخال:

- إشارات التحكم عن بعد: يقوم المشغل بإصدار أوامر مثل "تحرك للأمام" أو "تحرك لليسار" أو "دوران في اتجاه عقارب الساعة" عبر جهاز تحكم عن بُعد.

- نظام الملاحة: تستخدم السيارة رادار الليزر أو أجهزة الاستشعار البصرية أو رموز الاستجابة السريعة لإدراك موقعها وخريطتها الخاصة، وتخطط بشكل مستقل لمسار ما، وتحسب أوامر الحركة المطلوبة لتحقيق هذا المسار.

- حساب الخوارزمية: عند تلقي أمر توجيه، يستخدم نظام التحكم خوارزمية حركية عكسية لحساب السرعة والاتجاه الذي يجب أن تكون عليه كل عجلة.

- التنفيذ الحركي: يرسل "الدماغ" الأوامر المحسوبة إلى محركات كل عجلة، والتي تتحكم بدقة في سرعة وزاوية توجيه كل محرك.

إكسسوارات مخصصة:

والآن بعد أن فهمنا سير العمل الأساسي، قد لا تلبي العديد من الحلول الحالية احتياجاتنا بالكامل. نحن نقدم خدمات تخصيص إضافية.

خيارات تخصيص عربات النقل متعدد الاتجاهات خيارات التخصيص

| فئة التخصيص | خيارات محددة | التكوينات الشائعة |

| الأبعاد والحمل | حجم المنصة، سعة الحمولة | مخصص L/W/H، الحمولة المقدرة |

| مادة الجسم | مادة الهيكل الرئيسي | الفولاذ المقاوم للصدأ، والفولاذ الكربوني، وسبائك الألومنيوم، واللدائن الهندسية |

| الوظائف الأساسية | نظام الرفع، أجهزة التثبيت | الرفع الهيدروليكي، وحواجز الحماية، وحواجز الحماية، والحوامل، والأجهزة المخصصة |

| نظام التشغيل | نوع العجلة وتخطيطها | عجلات من البولي يوريثان، عجلات نايلون، عجلات دوارة، عجلات صلبة، مكابح |

| السلامة ووضع العلامات | ميزات السلامة، المظهر الخارجي | المصدات، وأضواء التحذير، والشعارات، والألوان، وأرقام الهوية |

ما سبق هو خيارات التخصيص الشائعة لدينا. إذا كانت لديك أي احتياجات تخصيص أخرى، فلا تتردد في الاتصال بنا. سيكون لدينا مصممين محترفين لتزويدك بمزيد من الحلول المخصصة.

بعد فهم مبدأ عمل العربات المتحركة متعددة الاتجاهات، دعنا نستكشف أنواعها وسيناريوهات تطبيقها.

أنواع العربات المتحركة متعددة الاتجاهات وتطبيقاتها

عربة متحركة متعددة الاتجاهات مقاومة للانفجار: مركبة متخصصة مصممة للبيئات الخطرة التي تحتوي على غازات أو غبار قابل للاشتعال أو الانفجار، مما يزيل أي مصادر طاقة محتملة يمكن أن تؤدي إلى حدوث انفجار. يشيع استخدامها في مصانع البتروكيماويات، ومرافق الطيران، ومستودعات الذخيرة العسكرية، ومصانع الأدوية.

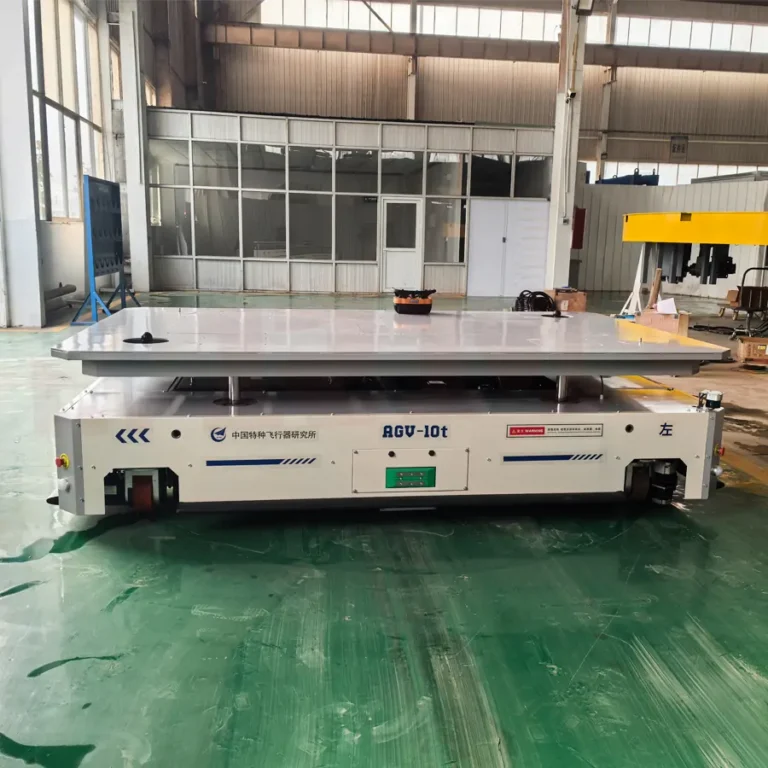

عربة متحركة متعددة الاتجاهات للخدمة الشاقة: المركبات الهندسية المستخدمة لنقل الأحمال التي يتراوح وزنها بين 10 و500 طن. وتشمل ميزاتها الرئيسية تكوينات متعددة العجلات (8 عجلات أو 12 عجلة أو أكثر) مع أنظمة دفع موزعة، وهياكل مركبات عالية القوة، ومحركات عالية العزم لتحقيق قدرة استثنائية على تحمل الأحمال والتحكم الدقيق. وهي تُستخدم عادةً في تصنيع المعدات الثقيلة والفضاء وبناء السفن وصناعة الطاقة.

الخدمات اللوجستية والتخزين AGV/AMR: الروبوتات الذكية التي تدمج أنظمة الملاحة (مثل الملاحة بالليزر SLAM والرؤية ورموز الاستجابة السريعة) والاستشعار وأنظمة الجدولة لتحقيق مناولة المواد وإدارة المعلومات بشكل آلي بالكامل. يشيع استخدامها في التجارة الإلكترونية ومخازن التجزئة والمصانع الذكية وتجميع السيارات.

عربة متحركة متعددة الاتجاهات لسلسلة التبريد: نوع من المركبات مصمم خصيصًا لبيئات التبريد ذات درجات الحرارة المنخفضة، مع بطاريات ومكونات إلكترونية وإطارات وأنظمة تشحيم مصنوعة من مواد وتقنيات مقاومة لدرجات الحرارة المنخفضة لضمان التشغيل المستقر والموثوق في البيئات القاسية. تُستخدم عادةً في صناعة أشباه الموصلات، وصناعة شاشات العرض، وتجميع الأجهزة الدقيقة، والفضاء.

منصة متعددة الاتجاهات غير قياسية مخصصة غير قياسية: هذه ليست فئة منتجات قياسية ولكنها حل مخصص للغاية تم تطويره استنادًا إلى المنصة المتنقلة متعددة الاتجاهات القياسية، مع دمج وحدات عميقة مثل الأذرع الروبوتية وأنظمة الرؤية والأدوات المتخصصة وفقًا لعمليات الإنتاج الفريدة للعميل ومتطلباته.

الخلاصة:

من خلال المحتوى أعلاه، تعرفنا على مبادئ عمل عربات النقل متعددة الاتجاهات وأنواعها وسيناريوهات تطبيقها. إنها معدات مناولة مهمة لا غنى عنها في مجال الخدمات اللوجستية الصناعية، وستصبح حلاً رئيسيًا لمزيد من الشركات في مواجهة تحديات المناولة. نحن شركة تصنيع صينية متخصصة في عربات النقل المخصصة. إذا كانت لديك أي مشاكل متعلقة بالمناولة، يُرجى الاتصال بنا على الفور، وسنقدم لك أحدث الحلول.