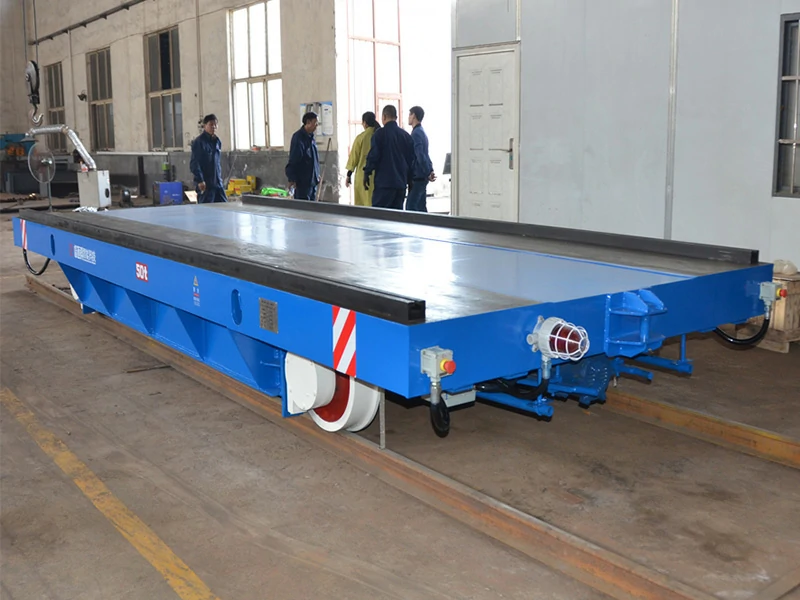

A coil transfer trolley is industrial transport equipment specifically designed for moving cylindrical materials such as steel coils. Its central frame features a V-shaped support bracket or adjustable groove structure, ensuring materials remain stable during transport without rolling or slipping. This enables precise, constant-speed, and safe transportation.

Steel coil transfer carts offer high load capacity, safety, reliability, and ease of operation. They are commonly used for medium-to-short distance handling between production lines, warehouses, and loading/unloading areas. With various subtypes available, how does one select the appropriate coil transfer trolley? First, we must understand its primary types.

Main Types of Coil Transfer Trolley

Different types of steel coil transfer carts exhibit distinct characteristics in operating methods, structural configurations, and applicable scenarios. Common types are as follows:

| النوع | Operating Method | Power Supply | Key Features | Suitable Scenarios |

|---|---|---|---|---|

| Rail-Mounted Coil Transfer Trolley | Operates on fixed rails | Powered by overhead conductor rails, cable reels, or batteries | Smooth operation, precise positioning, high load capacity, suitable for continuous operation | Steel rolling mills, heat treatment shops, and long-distance fixed-route transportation |

| Battery-Powered Trackless Coil Cart | Free movement without track installation | Battery-powered | Agile steering with forward/reverse, lateral shift, and in-place rotation | Space-constrained, complex route, or cross-shop handling tasks |

| Hydraulic Lifting Coil Cart | Track or trackless operation | Electric hydraulic system drive | Lifting capability for interfacing with platforms/production lines of varying heights | Material transfer between production lines, loading/unloading operations |

| AGV Coil Transfer Cart | Autonomous navigation along programmed routes | Battery-powered + intelligent control system | Unmanned operation, precise positioning, MES/WMS system integration | Smart manufacturing plants, automated warehousing systems, and high-end production workshops |

Summary Recommendations:

- Rail-guided equipment emphasizes stability and high load capacity.

- Rail-free and tow-type equipment prioritizes flexibility and cost-effectiveness.

- Hydraulic lift models suit production environments requiring height alignment.

- AGV automated models are the primary choice for smart manufacturing.

After learning about the types and characteristics of coil transfer carts, let’s explore the factors that influence their selection.

Factors for Choosing Coil Transfer Trolley

When procuring a coil transfer cart, enterprises must conduct a comprehensive evaluation from multiple perspectives, taking into account their own production processes and operational environments. The following are equipment-specific factors influencing selection:

Load Capacity and Compatibility

Determine the weight and dimensions of the steel coils, specifying the maximum single-coil weight, coil diameter, and stacking method. Ensure the load capacity includes a safety margin, typically recommending a rated load exceeding the maximum coil weight by at least 20%. The width and angle of the V-shaped support groove must match the coil diameter to enhance stability and safety. For handling multiple coil specifications, opt for an adjustable groove design to improve adaptability.

Operating Environment

For fixed, long-distance transport routes, rail-guided transfer carts are optimal. For cross-area handling or variable routes, trackless electric transfer carts offer greater flexibility. Additionally, ground load capacity, slope gradients, turning radius, and environmental factors (e.g., high temperatures, dust, or explosion-proof requirements) must be pre-evaluated and calculated to ensure long-term stable operation of the coil transfer cart under actual working conditions.

Power Supply Methods

Common power supply methods for coil transfer trolleys include conductor rail power, cable reel power, and battery power.

- Cable reel power supply is suitable for short-distance, fixed-route scenarios. It offers low cost but has limited mobility.

- Conductor rail power supply is ideal for long-distance, high-frequency usage scenarios, enabling continuous power supply but requiring complex installation.

- Battery power supply eliminates the need for cable laying, making it suitable for multi-area transportation. It offers easy maintenance and high flexibility.

Safety Protection

Coils are high-density heavy loads, making safety a critical consideration in selection. Coil Transfer Trolleys should feature soft start/stop, anti-slip V-grooves, audible/visual alarms, and emergency stop buttons. Intelligent models should additionally incorporate collision detection, path obstacle avoidance, and automatic alarm systems to ensure safe operation in complex environments.

Recommendations for Choosing Coil Transfer Trolley Manufacturer

- Evaluate industry experience: Prioritize suppliers with extensive project experience and professional manufacturing capabilities.

- Evaluate Technical Capabilities: Prioritize suppliers with proven design and R&D expertise in coil handling equipment.

- Emphasize After-Sales Support: Select manufacturers offering comprehensive installation, commissioning, maintenance, and technical support services.

- Verify Spare Parts Availability: Ensure long-term supply of genuine spare parts to maintain stable equipment operation.

- Assess Reputation and Responsiveness: Choose reputable manufacturers with prompt response times to minimize future risks.

- Consider Long-Term Partnership Potential: Prioritize establishing enduring collaborations with companies demonstrating mature technology and robust service capabilities.

Manufacturers with proven engineering experience and comprehensive after-sales systems significantly reduce future maintenance and retrofitting costs for enterprises.

Benefits of Choosing the Right Coil Transfer Trolley

- Enhanced Handling Efficiency: Enables rapid loading/unloading and transportation, saving labor and time.

- Operational Safety Assurance: Reduces risks associated with manual handling of heavy loads and prevents coil slippage accidents.

- Optimized Space Layout: Improves internal logistics flow through flexible scheduling.

- Supports Smart Upgrades: Integrates with automated production lines and warehousing systems to advance digital factory development.

- Extended Equipment Lifespan: High-strength structure and stable control systems ensure long-term operational reliability.

Selecting the right coil transfer cart suited to your specific operating conditions is essential for improving transport efficiency, ensuring production safety, and controlling costs. If you wish to learn more about steel coil transfer carts, please refer to the article: ما هي عربة نقل لفائف الصلب؟

الخلاصة:

The coil transfer trolley is a critical logistics asset whose selection impacts transportation efficiency, production safety, and cost control. When purchasing, enterprises should thoroughly evaluate factors such as load capacity, operating environment, power supply methods, and safety features, partnering with manufacturers offering proven technology and comprehensive service support.

REMARKABLE is a Chinese manufacturer specializing in customized transfer trolleys, backed by extensive experience and mature technology. If you have requirements, اتصل بنا immediately for the most suitable solution.