REMARKABLE has developed a bespoke automated RGV (Rail Guided Vehicle) tailored for the defence manufacturing sector. This intelligent RGV not only handles material transfer tasks but also plays a significant role in assembly and operational workflows, delivering efficient and secure automated support for military production. This article explains what a customised automated RGV is, providing detailed insights into this RGV transfer vehicle and its supplier.

What is a Customised Automated RGV?

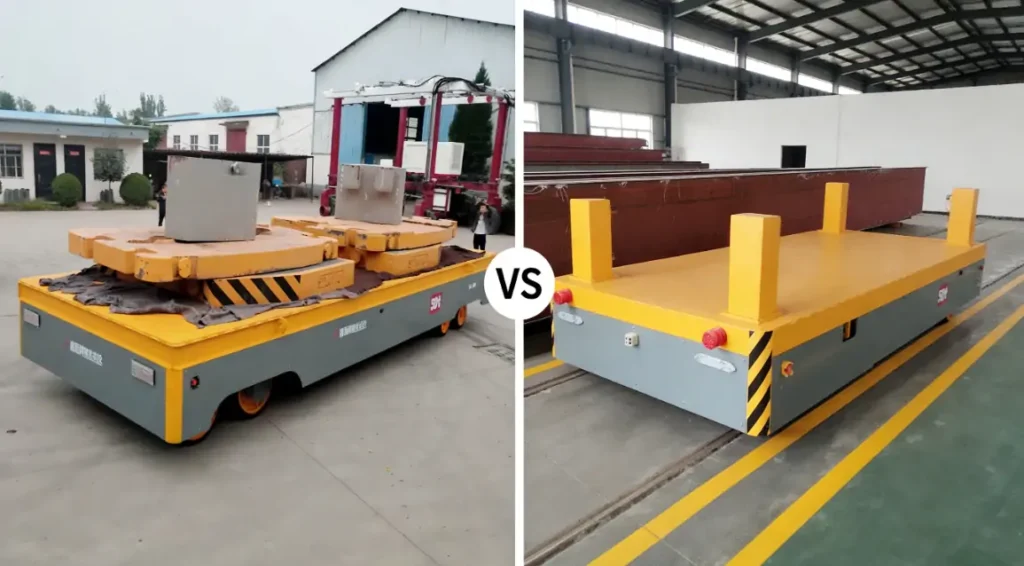

A customised automated RGV is a system-level design based on conventional RGVs, tailored for specific operational scenarios. Key customisation aspects include:

- Work surface and fixture structures customised to component and process requirements

- Functional modules integrated according to the actual workflow

- Operational performance matched to production cycle times

- Control systems capable of deep integration with production line equipment

The above outlines the customisation philosophy of manufacturer REMARKABLE. Customised intelligent RGVs are well-suited for high-standard, highly complex manufacturing environments such as defence applications. Let us now explore this industrial transfer vehicle.

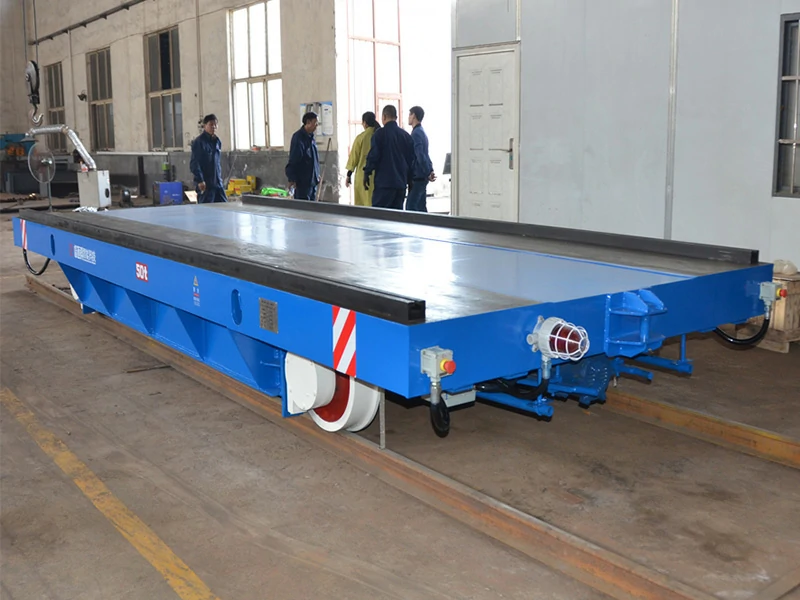

Customised Automated RGV

Within defence manufacturing contexts, an RGV’s value extends beyond mere transport to encompass process integration. Below, we detail this automated RGV transfer vehicle.

Multi-Degree-of-Freedom Fixture Structure

Military products are often large-volume and structurally complex, demanding precise workpiece orientation adjustments during assembly and inspection.

REMARKABLE’s RGV employs a custom fixture platform integrating 360° rotation and up to 60° lateral tilt capability, enabling workpiece angle adjustments during transit. Evolving from a basic transport device into a process-aiding platform, it significantly reduces secondary lifting and manual intervention in conventional workflows. This enables rapid, precise alignment of workpieces between stations, enhancing assembly efficiency while mitigating operational risks.

Integrated Mobile Power Supply Functionality

In military assembly environments, certain workstations demand high continuity and stability of power supply, whereas fixed power sources often constrain equipment flexibility.

This customised automated RGV is engineered as a mobile power supply unit, delivering stable electrical support to assembly tools and inspection equipment during both operation and stationary periods, with compatibility across multiple current types. By integrating the power supply into the RGV system, it eliminates issues such as frequent power plugging/unplugging and redundant cabling, ensuring a more continuous and secure operational process.

High-Speed Operational Performance

Military production typically demands long-distance, high-frequency transfers. This RGV transfer vehicle has been optimised for operational performance.

Capable of accelerating from standstill to 2.5 m/s and reaching a maximum operational speed of 300 m/min, it enables rapid workstation switching while maintaining operational stability. Its high-speed capability effectively reduces non-productive time between processes, aligning with high-takt automated production lines to enhance overall manufacturing efficiency.

Deeply Customised Control System

Military manufacturing demands exceptional equipment reliability and controllability, requiring adaptation to complex defence environments.

This customised RGV employs a mature automation control solution, with tailored control logic according to project requirements. It achieves precise track operation, stable positioning, and signal interlocking with production line equipment. Flexible switching between automatic, semi-automatic, and manual operating modes enables the RGV to adapt to diverse complex conditions, ensuring stable operation and high safety standards.

The foregoing provides a brief overview of this customised automated RGV transfer cart. Its suitability for military applications hinges on manufacturers possessing mature customisation expertise in both manufacturing and engineering. Below, we examine the manufacturer REMARKABKE.

REMARKABLE Supplier Manufacturing Capabilities

1. Specialising in the R&D and manufacturing of transfer vehicles and automated logistics equipment

With extensive experience in rail-guided transfer vehicles and automated handling systems, I possess deep expertise in heavy-duty, high-precision and complex operational conditions.

2. Extensive experience in bespoke, customised RGV projects

Accumulated mature design and implementation expertise across diverse bespoke projects, capable of addressing structural complexity and process variations common in defence projects.

3. Structural, functional and system-level customisation tailored to defence requirements

Mechanical structures, functional modules and control logic are optimised through targeted design aligned with operational scenarios.

4. End-to-end project capability from conceptual design to delivery

Comprehensive coverage spanning planning, design and manufacturing, system commissioning and on-site handover ensures seamless project execution.

5. Suitable for high-security and complex process environments

Equipment design prioritises stability and reliability, ensuring long-term operation within demanding production settings such as defence manufacturing.

Drawing upon extensive project experience and engineering practice, REMARKABLE continually delivers practical automated transfer solutions for defence and high-end manufacturing sectors.

Conclusão:

This article has introduced the customised automated RGV system for defence manufacturing and its supplier. Should you require an intelligent RGV transfer vehicle tailored to your specific operational conditions, we invite you to contactar-nos to explore the REMARKABLE solution further.