Automated Guided Vehicle, also known as Autonomous Guided Vehicle, Self-Guided Vehicle or Mobile Robot, is a kind of automated handling vehicle. AGV is an intelligent handling system composed of multiple Automated Guided Vehicles with different intelligent system settings and multiple handling equipments. They can transport goods or materials in a factory environment without manual operation or driving. Commonly used in manufacturing plants, warehouses or distribution centres. This article will introduce different types of AGV, please read on.

Different Types of Automated Guided Vehicles

There are many different types of Automated Guided Vehicles , each designed to meet different material handling needs and work environments. We will now explain the common types of AGV Automated Guided Vehicle

Automated Guided Cart (AGC)

The Automated Guided Cart is the simplest form of AGV, with a single function, generally point-to-point transport, without functions such as lifting and assembly. They usually follow a predetermined path or magnetic track. They are often used to transport smaller loads or items, such as assemblies or parts on an assembly line, or to carry tools, scrap and equipment. These are

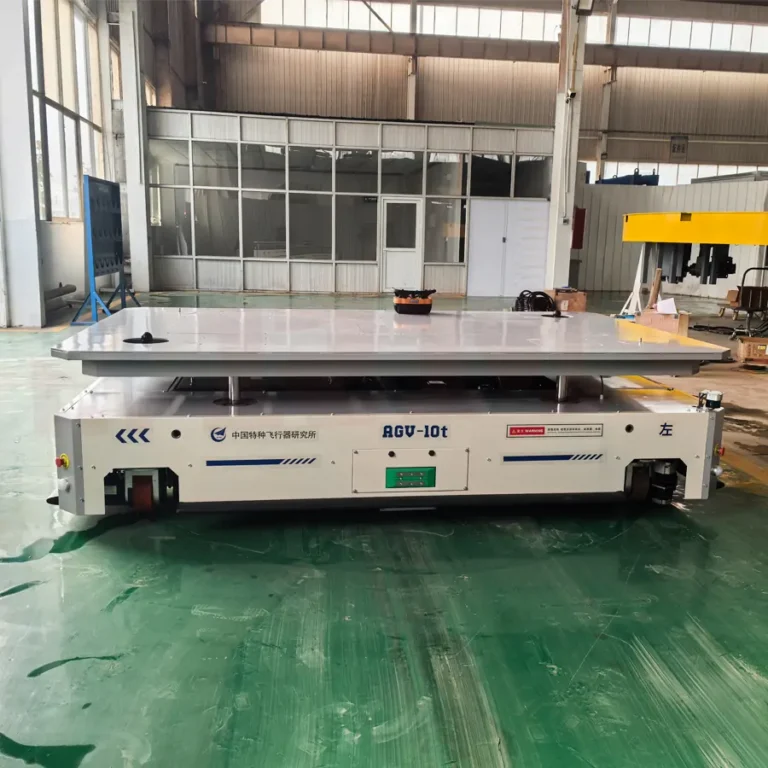

Automatic Mold Trackless Transfer Cart

The Automatic Mold Trackless Transfer Cart travel path can be changed flexibly according to the warehouse location requirements, production process flow, etc., and the cost of running path change is very low compared with the traditional conveyor belt and rigid transmission line. The AGV is usually equipped with a loading and unloading mechanism, which can automatically interface with other logistics equipment to realize the automation of the whole process of loading and unloading of goods and materials.

Towing Automated Guided Vehicle AGV

Towed Automated Guided Vehicle , commonly used for automated towing, trailers or other wheeled equipment. They are fitted with hooks or couplers for attachment and transport. Towed AGV are often used when there is a need to move several smaller loads of equipment at the same time, or to haul different materials for handling transfers. For example to transport materials to a production line.

For heavy load handling, we have heavy duty trucks in conjunction with AGV that can handle large assembly parts, heavy castings and coils, steel fabrication, heavy machinery and other heavy industrial load handling jobs.

There are also models with self-loading capabilities and advanced steering options (standard, pivot or omni-directional) to navigate handling in confined spaces and complex industrial environments.

Hybrid Automated Guided Vehicle AGV

Hybrid Automated Guided Vehicle combine AGV technology with manual operation. They can operate autonomously, following pre-programmed paths, or be manually operated when required. Hybrid AGV are useful in flexible and complex work environments where material handling can be operated both automatically and manually.

Automated Guided Vehicle Robots

Autonomous Mobile Robots (AMR), like Automated Guided Vehicle (AGV), are Automated Guided Vehicle Robots and may look very similar to AGV at first glance. However, the way they operate is different.

AMR are more advanced than AGV because they are equipped with sensors and cameras that allow them to inspect and interact with their surroundings in real time. They don’t rely on pre-defined paths, similar to the way smart cars use GPS to navigate. This means that AMR can avoid obstacles, re-route as needed, and adapt to changes in the work environment.

Of course, we also have Heavy-Duty Automated Guided Vehicle , Explosion-Proof Automated Guided Vehicle , and Cold Chain Automated Guided Vehicle , which are customised according to different working environments and special requirements.

Conclusion:

By analyzing the various types of automated guided vehicles, I believe you have understood the application scenarios of different models. Whether it is lightweight traditional AGC or intelligent customized AMR type AGV, Remarkable has mature R&D and production experience.

If you encounter technical problems in the use of automated guided vehicles, or have procurement needs, please feel free to contact us. We will provide you with professional technical support and cost-effective customized solutions.