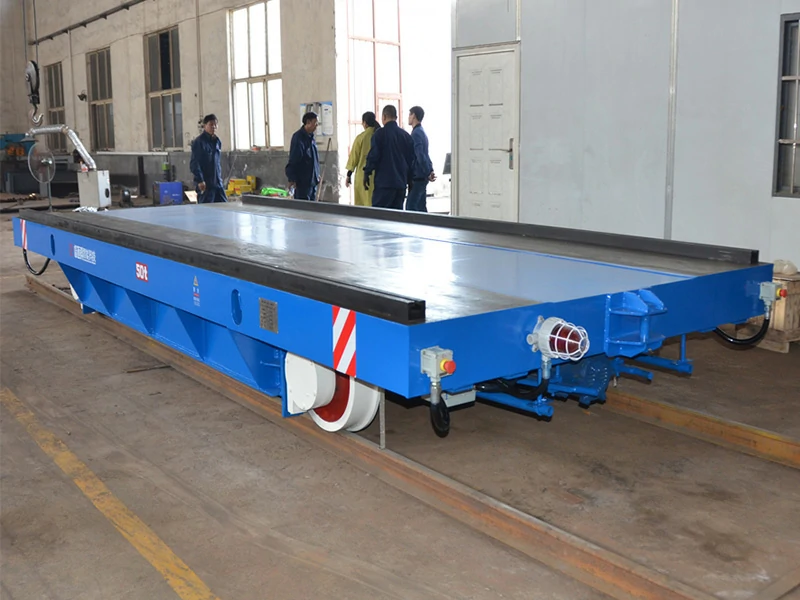

Die Transfer Carts are an important industrial conveying device that operates electrically on tracks or the ground to safely and efficiently transport workpieces between production workshops, warehouses, and workstations. Featuring high load capacity and simple operation, it is widely used in industries such as automotive manufacturing, injection molding, and so on. This article will explore its working principles, advantages, and how to select the appropriate die transfer cart.

Working Principle of the Die Transfer Cart

Power is supplied to the drive motor via batteries, cable reels, or rail-based power systems, propelling the wheels along the ground or tracks to execute forward/reverse movement, steering, and speed adjustments. Combined with a high-strength platform structure, hydraulic lifting systems, or positioning devices, it ensures smooth mold transportation and precise alignment. Heavy-duty die transfer carts are typically operated via remote control or handheld handles to execute start/stop, steering, and speed adjustments, enhancing safety and reliability during heavy mold handling.

Having understood the working principle of the die transfer car, let’s look at its key advantages.

Key Advantages of Die Transfer Carts

Heavy-Duty Capacity: Supports custom load ranges from 5 tons to 300 tons and beyond, suitable for transporting large molds and heavy tooling.

Enhanced Safety: Platforms can incorporate anti-slip steel plates, limit stops, side rails, and emergency braking systems to reduce risks of mold slippage and operator error.

Enhanced Durability: Constructed with high-strength welded frames and industrial-grade drive components, ensuring stable reliability under long-term heavy-load operation with low maintenance frequency.

Flexible Mobility: Choose between rail-mounted die carts or steerable die handling carts based on workshop layout, accommodating complex routes and confined spaces.

Automation Ready: Upgradeable to an automated guided vehicle (AGV), enabling unmanned intelligent transport via laser or magnetic strip navigation for automated production lines and smart factories.

Low Maintenance Cost: Simple structure and low failure rate result in maintenance costs lower than traditional handling equipment, like forklifts, reducing long-term operational expenses.

Die transfer carts have the advantages mentioned above, making them essential handling equipment in modern mold manufacturing and large workpiece workshops. So, do you know what types of die transfer vehicles are available? Let’s take a look.

Common Types of Die Transfer Carts

Die transfer cars come in various types. Below are their main types for reference.

| Tip | Özellikler | Kapasite | Typical Applications |

|---|---|---|---|

| Rail-Mounted Transfer Cart | Fixed rail operation ensures high stability, ideal for long-distance transport | 10–300+ tons | Die transfer between stamping lines, fixed internal production line transport |

| Battery-Powered Handling Cart | Equipped with a hydraulic lifting platform for die alignment and loading/unloading | 5–200 tons | Battery-Powered Handling Cart (Battery-Powered Trackless) |

| Steerable Transfer Cart | Can rotate in place, suitable for confined spaces with low floor requirements | 5–100 tons | Narrow aisles, flexible transitions between workshop stations |

| Hydraulic Lift Die Cart | Smart manufacturing plants, automated production lines, and unmanned logistics systems | 5–80 tons | Injection molding die changes, stamping equipment mold installation/removal |

| Automated Die Transfer Carts(AGV) | Unmanned operation, laser navigation, MES/ERP system integration | 5–50 tons | Smart manufacturing plants, automated production lines, and unmanned logistics systems |

We REMARKABLE supports customized solutions for all transfer cart types. If you’re interested in our die transfer carts, please contact us. We will provide you with the most suitable solution.

How to choose the right die transfer cart?

When choosing a die transfer cart, key factors such as load capacity and workshop environment must be considered to ensure efficient and long-term stable operation. Here are the key points buyers should focus on during selection:

Based on load capacity: Use the maximum mold weight as the baseline. Choose a model with a load capacity ≥ 1.2–1.5 times the maximum mold weight to enhance long-term operational safety.

Based on the workshop route: for fixed routes and large transport volumes, choose rail-mounted transfer trolleys; for cross-regional or flexible handling, choose battery trackless transfer carts; for narrow spaces, choose steerable transfer carts.

Other Requirements: Pay attention to whether die loading/unloading, die changeovers, or alignment with presses/injection molding machines are involved. If so, consider models with hydraulic lifting platforms or automatic alignment systems.

Automation Evaluation: Assess current needs and plans. For unmanned operation or intelligent scheduling, select transfer cars supporting AGV/AMR navigation or featuring automation expansion interfaces.

Choose a high-quality manufacturer: Prioritize suppliers with proven experience in die transfer carts, offering customizable designs and comprehensive after-sales support to enhance equipment stability and reduce operating costs.

Sonuç:

Through this article, we have learned about the working principles and advantages of heavy-duty die transfer carts, as well as how to select the appropriate die transfer vehicle. It not only efficiently and safely completes die handling but also significantly reduces labor costs and operational risks.

If your business requires transfer cart equipment, please feel free to Bize ulaşın anytime. We are committed to providing customized solutions, offering you the most suitable products and premium service.

.webp)