Heavy duty transfer carts meeting requirements for efficiency, safety, and the transportation of large-scale equipment have become essential heavy-load logistics equipment within factories. They are widely utilised across industries such as steel and mould manufacturing. This article analyses their primary application sectors and suitable transfer cart types, guiding enterprise selection.

Heavy Duty Transfer Carts for the Steel & Metal Industry

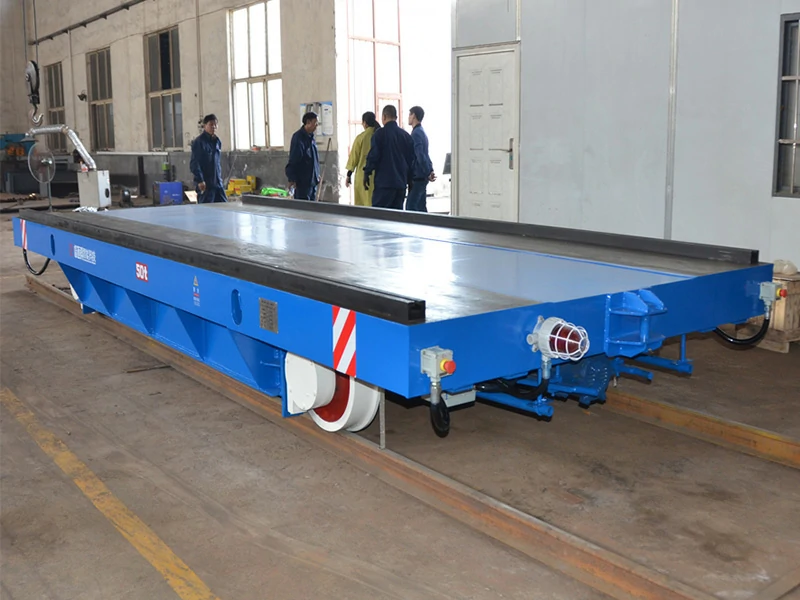

Materials in the steel industry, such as steel coils, aluminium coils, and metal plates, are extremely heavy and vary greatly in form. They require multiple transfers between processes, including rolling, annealing, storage, and cutting. Equipment with high load-bearing capacity, stable structure, and the ability to prevent material rolling must be selected.

Typical Handling Scenarios

- For transporting steel coils from warehouses to decoilers, delivering finished coils to storage, or distributing plates across workshops, the тележка для переноса рулонов is employed. Its platform is typically designed as a V-frame to secure coils and prevent rolling, suitable for loads ranging from 10 to 150 tonnes.

- For handling long or large structural components like plates and metal assemblies, rail-guided heavy duty transfer carts are commonly employed. These are suited for high-frequency, repetitive path operations.

- Where factory routes are variable, heavy-duty AGVs equipped with laser or magnetic navigation offer high flexibility, making them ideal for smart factory upgrades.

Тележка для переноса рулонов

Тележка для переноса рулонов Rail-Guided Heavy Duty Transfer Carts

Rail-Guided Heavy Duty Transfer Carts Heavy-Duty AGVs

Heavy-Duty AGVs

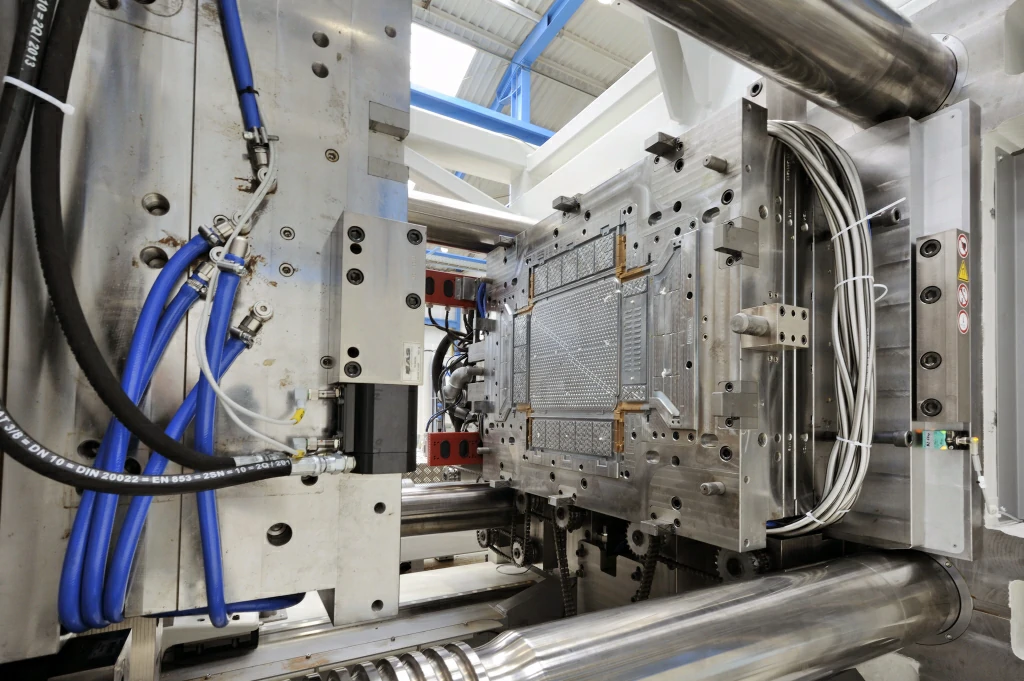

Heavy Duty Transfer Cart for the Mould & Die Industry

Injection moulds, stamping dies, and similar equipment are typically heavy, high-value items with stringent precision requirements. Any collision or tipping incident can result in substantial losses. Furthermore, moulds require frequent changes, demanding handling equipment that is stable, high-precision, safe and capable of precise docking.

Typical Handling Scenarios

- Moulds are transferred between mould storage facilities and injection moulding or stamping machines, as well as during maintenance and replacement operations. Typically, die transfer carts are employed, configurable with hydraulic lifting platforms and roller decks to achieve precise alignment and stable support.

- For automated mould change production lines, heavy-duty AGVs for die handling are generally selected. Utilising laser navigation, these enable automatic docking and mould changes, enhancing production efficiency while reducing manual operation risks.

Die Material Transfer Trolley

Die Material Transfer Trolley Heavy-Duty AGVs

Heavy-Duty AGVs Тележки для переноса штампов

Тележки для переноса штампов

Heavy Duty Transfer Cart for the Automotive Industry

Automotive manufacturing encompasses multiple workshops, including welding, final assembly, and powertrain systems. Components such as chassis, undercarriages, battery packs, and engines are bulky and heavy, demanding stringent stability during handling. Concurrently, rapid production cycles necessitate frequent cross-workshop transfers, requiring long-distance, continuous, and high-precision logistics transportation.

Typical handling scenarios

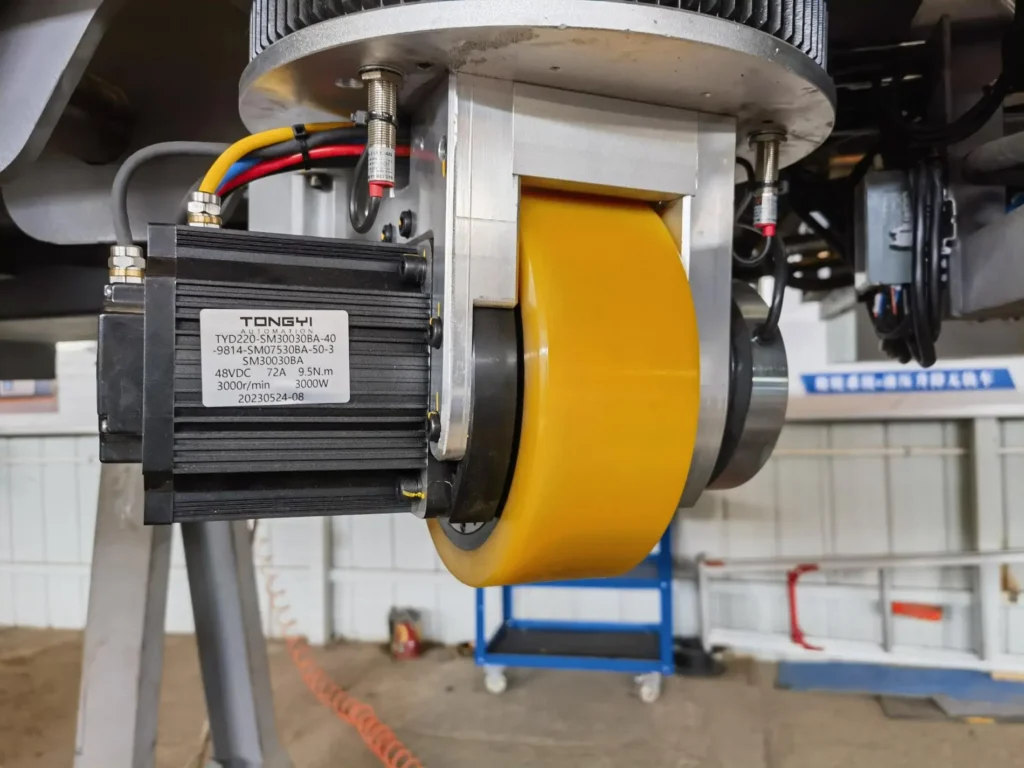

- For transporting vehicle frames from welding lines to final assembly lines, or delivering large structural components across workshops, heavy-duty AGVs are typically employed. Examples include magnetic navigation AGVs, which enable automated path planning and integrate with MES systems to enhance overall logistics automation.

- Where routes are fixed and single-direction shuttle transport is required within workshops, efficient and cost-controlled rail transfer carts are selected.

- For large body components, battery-powered trackless transfer carts are commonly employed, suitable for long-distance and cross-zone handling.

Heavy-Duty AGVs

Heavy-Duty AGVs Rail-Guided Transfer Carts

Rail-Guided Transfer Carts Battery-Powered Trackless Transfer Carts

Battery-Powered Trackless Transfer Carts

Heavy Duty Transfer Carts for the New Energy Industry

Equipment within the new energy industry—such as power battery packs, wind turbine nacelles, and photovoltaic installations—is typically large in size and high in value, demanding exceptional stability and precision during handling. This is particularly critical in lithium battery pack assembly workshops, where batteries exhibit extreme sensitivity to vibration.

Typical Handling Scenarios

- For scenarios such as transferring battery modules between pack lines or moving wind turbine blades/nacelle structures across workshops, trackless heavy-duty transfer carts are typically selected. These offer smooth, vibration-free operation and can be fitted with customisable soft-connection surfaces to protect sensitive materials.

- For exceptionally heavy new energy equipment like transformers or wind power components, customised hydraulic lifting transfer carts are employed, supporting precise height adjustment and heavy-load support.

- Highly intelligent new energy factories require AGV to achieve unmanned production and flexible logistics scheduling.

Hydraulic Lifting Transfer Carts

Hydraulic Lifting Transfer Carts Trackless Heavy-Duty Transfer Cart

Trackless Heavy-Duty Transfer Cart Heavy-Duty AGVs

Heavy-Duty AGVs

Heavy duty transfer carts offer high load-bearing capacity, safety, flexibility, and customisability, making them essential logistics equipment across steel, mould, automotive, and new energy industries. The appropriate transfer cart solution must be selected based on specific operational requirements, tailored to the actual working conditions.

Заключение:

Through the preceding article, we have identified the primary industries utilising heavy duty industrial transfer carts and analysed the appropriate cart types for each sector. Should you currently require a transfer cart, please связаться с нами. We shall provide you with the most suitable transfer cart solution.