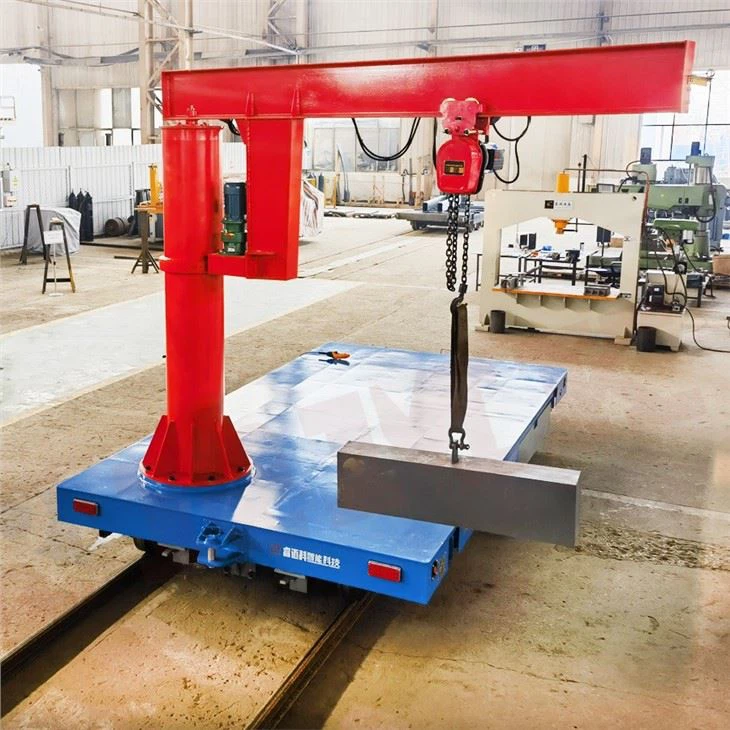

This 30-ton steel coil transfer cart was custom-manufactured for an automotive plant in Jilin, addressing the challenges of steel coil handling, lifting and safety. It also serves as our competitive 30-tonne hydraulic lifting transfer cart for the Turkish market, resolving the issue of transporting chemicals both within and outside workshops. This lift-type omnidirectional coil transfer cart is a specialised transport solution designed for steel coil handling, equally suitable for applications in steel mills, metal processing plants, warehousing, and logistics operations.

- Model: RWP

- Load Capacity: 30 Tons

- Dimensions: 3933 × 2200 × 650 mm

- Lifting Stroke: Hydraulic lifting, 150 mm

- Power Supply: Maintenance-free battery (electric drive)

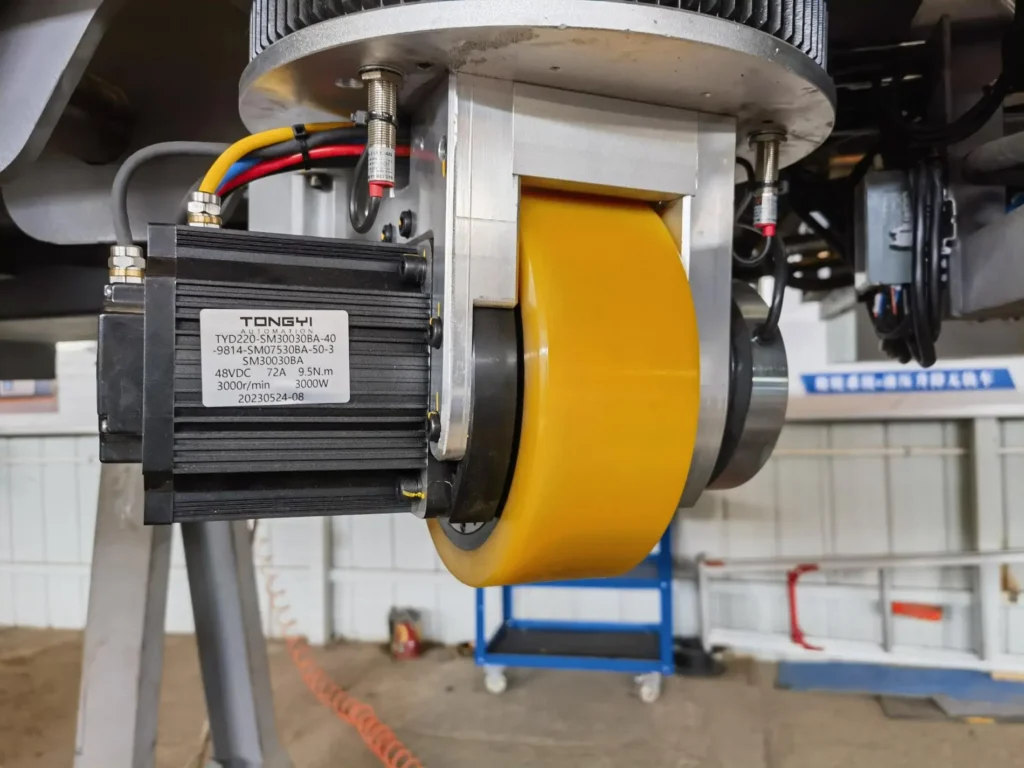

- Turning Method: Hydraulic steering / Omnidirectional steering wheel

- Speed: 0–20 m/min (stepless speed regulation)

- Customization: Custom production available, including additional components, etc.

Working Principle of Steel Coil Transfer Cart

The 30-ton steel coil transporter is a common omnidirectional transfer trolley. It features flexible self-operation, energy efficiency, environmental friendliness, convenient transportation, and strong customizable functionality, making it highly popular and widely adopted.

Power Supply: Maintenance-free lead-acid battery

Operation Mode: Wireless remote control or wired operation

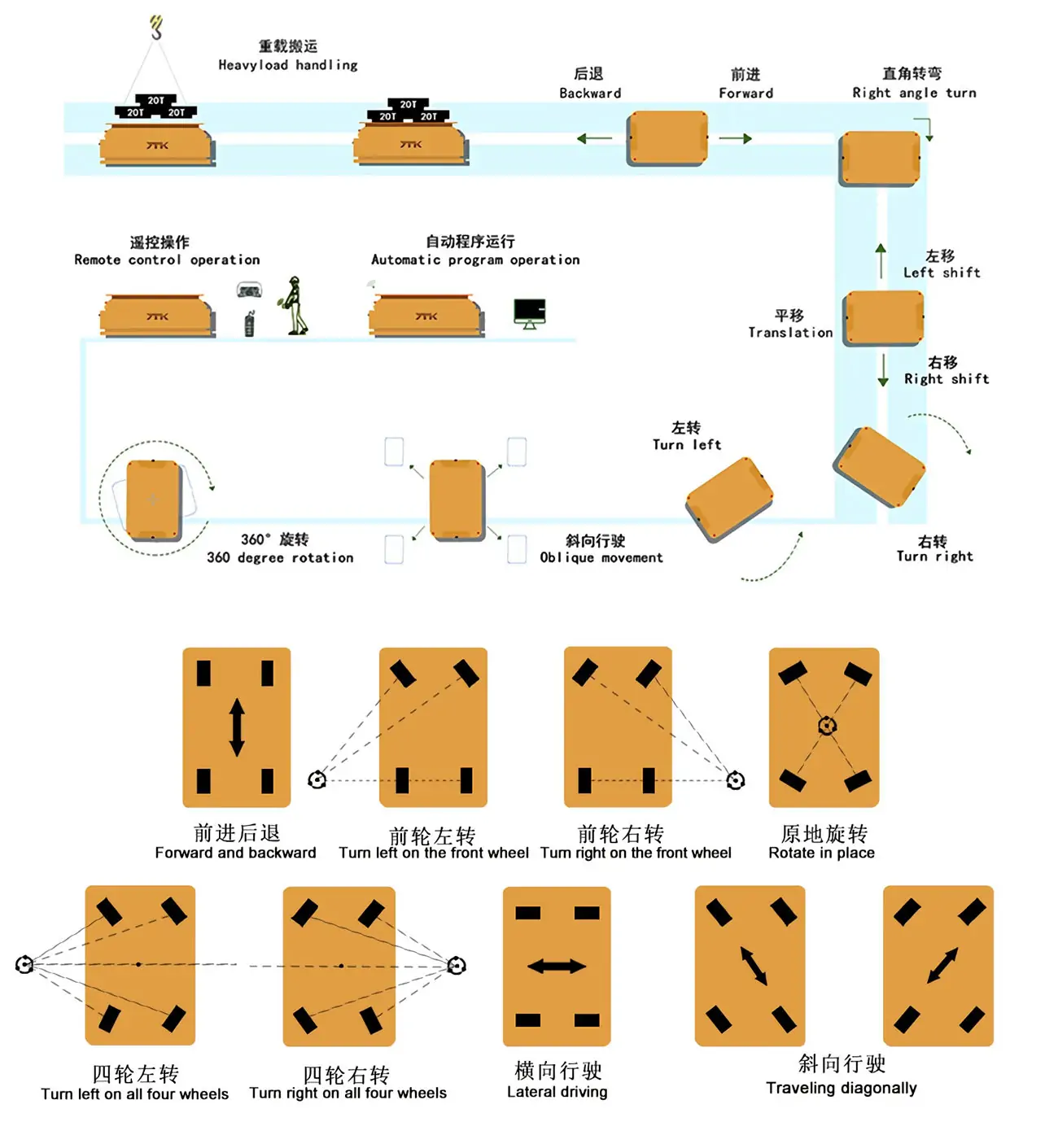

Movement Trajectory: Forward, backward, left, right, non-stop turning, and moderate climbing capability

Working Principle:

The operating principle of this equipment involves the integrated collaboration of power, control, execution, and safety protection systems. Its core function lies in precisely controlling mechanical movements through commands to achieve flexible material handling and accurate lifting of heavy objects:

Power

Principle: A high-capacity battery pack supplies power to the entire system (drive motors, hydraulic pump station, controllers, sensors). Upon power-up, the main control system automatically performs a self-check to diagnose the status of motors, sensors, hydraulic units, and communication links. After passing the self-check, the system enters standby mode.

2. Command

Principle: The remote controller transmits operational commands (e.g., forward, reverse, lift) to the transporter’s controller. Upon receiving commands, the vehicle decodes them through system modules, converting signal instructions into actionable control signals sent to various mechanical components.

3. Onboard Main Controller

- Principle: The onboard main controller serves as the device’s “brain.” Upon receiving commands, it performs high-speed computational analysis:

- For movement commands: The controller decomposes direction and speed commands into specific drive signals and steering signals.

- For lifting commands: The controller issues start/stop and pressure control signals to the hydraulic system control unit.

4. Coordinated Execution

The system synchronously or sequentially drives two major actuators based on the command type:

- A. Omnidirectional Movement Execution:

- The controller sends calculated angle and speed commands to the servo motors of each steering wheel.

- Each wheel independently and precisely adjusts its angle according to commands, coordinating with the drive wheels’ rotational speed to synthesize the required motion trajectory (straight, diagonal, lateral movement, or on-the-spot rotation).

- Progressive acceleration control activates, enabling smooth vehicle starts and preventing coil sway caused by abrupt acceleration.

- B. Hydraulic Lifting Execution:

- Upon receiving an “Ascend” command, the controller activates the electric hydraulic pump station.

- The motor drives the hydraulic pump to generate high-pressure fluid. This fluid flows through hydraulic lines, extending the piston rod of the lifting cylinder. This action raises the load-bearing saddle, lifting the steel coil.

- Displacement sensors integrated into the cylinder monitor the lifting height in real time, feeding back to the controller for precise positioning.

- Upon receiving a “lower” command, the controller opens the hydraulic valve. Under the coil’s own weight, oil slowly returns to the cylinder, enabling smooth descent.

5. Stopping and Holding

Principle:

- Movement Stop: The controller immediately cuts power to the drive motor and applies electromagnetic brakes, enabling the vehicle to stop smoothly.

- Lifting Hold: The hydraulic system’s pilot-operated check valve automatically closes, trapping fluid within the cylinder. This securely holds the lifting platform and load at any intermediate position, preventing slippage due to leakage and ensuring safety.

The 30-Ton steel coil transfer cart employs a closed-loop principle of “Command Input → Intelligent Control → Electro-Mechanical-Hydraulic Coordination” to convert robust battery power into precise mechanical actions, thereby safely and efficiently completing heavy steel coil handling tasks.

Steel Coil Transfer Cart Steering Mode

30-Ton Steel Coil Transfer Cart Safety Operating Procedures

Important Notice: Operators must be professionally trained and thoroughly familiar with these procedures. Please ensure you read the equipment manual before operating the equipment.:

Step 1

- Environmental Verification: Inspect the transfer cart’s travel path. Clear all ground obstructions, oil spills, and standing water. Ensure sufficient passage width and no overhead obstructions.

- Equipment Self-Check:

- Power Supply: Verify sufficient battery charge.

- Vehicle Structure: Inspect the chassis and saddle for visible deformation or damage.

- Hydraulic System: Check hydraulic fluid level and inspect lines for leaks.

- Safety Devices: Test emergency stop button, warning lights, and collision sensors for proper function.

- Wheels: Inspect wheels for integrity and ensure no foreign objects are lodged.

- Load: Verify the weight and diameter of the coil to be transported are within the equipment’s rated capacity. Ensure the coil is securely hoisted or positioned.

Step 2:

- Start Vehicle: Turn on the main power switch to initiate system self-check. After passing the self-test, activate the control panel. Select either manual operation or wireless remote control mode, then position yourself in a safe location to prepare for operation.

- Approach the coil: Using the directional buttons on the remote control, initiate slow movement. Steer the vehicle steadily to precisely position the V-shaped saddle directly beneath the coil.

- Confirm positioning: Visually verify that the coil is fully centered over the saddle’s load-bearing point.

Step 3:

- Lifting: Select the “Ascend” function on the remote control to activate the hydraulic system. Smoothly and slowly lift the coil off its original support base (approximately 10-20mm is sufficient). Observe whether the equipment remains stable and free of abnormal noises.

- Safe Transportation:

- Select an appropriate forward direction (straight, diagonal, or standard turn) and start at low speed.

- On wide passages, speed may be moderately increased but must not exceed the rated speed (20m/min).

- When approaching intersections or obstacles, decelerate in advance and sound the horn/flash lights to warn.

- Maintain steady operation, avoiding sudden acceleration, sharp turns, and abrupt braking.

Step 4:

- Target Position: Transport the coil to the target location, utilizing the omnidirectional movement function for precise alignment.

- Lowering and Unloading: After alignment, operate the remote control’s “Lower” function to slowly and steadily place the coil onto the designated support base. Once the coil is securely positioned, continue maneuvering the vehicle to fully disengage the saddle from the coil.

- Vehicle Withdrawal: Drive the vehicle out of the work area and park it in the designated safe zone.

- Operation Completion: Turn off the vehicle’s main power switch and complete the equipment usage log. If charging is required, connect the charger.

Safety Precautions:

- Strictly prohibit overloading! The maximum load capacity is 30 tons.

- Strictly prohibit carrying passengers! The vehicle is intended solely for cargo transport.

- Strictly prohibit moving the vehicle while the lifting platform is not fully lowered.

- Operators must keep their hands and feet clear of moving components such as the lifting mechanism and wheels.

- In case of abnormal conditions, immediately press the emergency stop button.

Videos Show

Custom Steel Coil Transfer Cart

Технические характеристики

| Technical Parameters Table Of RWP Trackless Electric Transfer Cart | |||||||||||

| Rated Load Capacity(t) | 5 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | |

| Размер стола (мм) | Длина | 2400 | 2700 | 2700 | 3000 | 3500 | 4000 | 4500 | 5000 | 6000 | 6000 |

| Ширина | 1500 | 1800 | 1800 | 2000 | 2200 | 2000 | 2200 | 2500 | 3000 | 3000 | |

| Высота | 470 | 550 | 600 | 700 | 700 | 800 | 900 | 1000 | 1000 | 1000 | |

| Ground Clearance(mm) | ≥50 | ≥100 | |||||||||

| Turning Radius(mm) | 2200 | 2500 | 2500 | 2800 | 3300 | 6000 | 6800 | 7500 | 9000 | 9000 | |

| Steering mode | Differential Steering | Hydraulic Steering | |||||||||

| Operation Method | Remote Control & Hand-Operated Pendant | ||||||||||

| Move Way | Forward, backward, turning while driving with no stop, and a 360° rotation | Forward, backward, turning while driving with no stop | |||||||||

| Running Speed(m/min) | 25 | 20 | |||||||||

| Motor Type | Low-voltage alternating current (AC) motor / brushless direct current (DC) motor | ||||||||||

| Brake Mode | Electromagnetic Brake | ||||||||||

| Protective Measures | Audible and visual alarm lamp+ Emergency stop button+Laser obstacle avoidance sensor(Optional)+Anti-collision contact edge(Optional) | ||||||||||

| Количество колес | 4 | 6 | 8 | ||||||||

| Drive Wheel Diameter(mm) | Ф360 | Ф400 | Ф400 | Ф450 | Ф500 | Ф500 | Ф600 | Ф550 | Ф550 | ||

| Wheel Material | Steel Core + Polyurethane | ||||||||||

| Battery Capacity(kW·h) | 5.5 | 8.5 | 10.5 | 14 | 18.5 | 18.5 | 30 | 37.8 | 45.3 | ||

| Battery Type | Lead-Acid Battery | Lithium Battery | |||||||||

| Battery Endurance | 5h(Customized As Needed) | 4h(Customized As Needed) | |||||||||

| Battery Charging Time | ≤7h | ≤5h | |||||||||

| Battery Charger | AC220V/AC380V | ||||||||||

| Ground type | Cement Floor、Steel Plate Ground 、Epoxy Floor, Asphalt Floor | ||||||||||

| Full-Load Climbing Capacity | 5% | 3% | |||||||||

| Working Environment | Temperature: -10°c~40°c; Humidity: 20%~80%, No Condensation (Customized for high-temperature and explosion-proof environments) | ||||||||||

| Vehicle Body Color | Customized | ||||||||||

| Other Functions | Battery Power Display, Over Voltage, Under Voltage, Over Current Protection etc | ||||||||||

| Notes: 1) Other table sizes and load capacities can be customized according to user requirements. 2) For hydraulic steering, a dual hydraulic steering system can be selected to reduce the turning radius based on site space constraints. 3) Battery type and operating time (battery endurance) can be customized to meet customer needs. 4)The product is subject to continuous improvement and upgrades; specifications in the table may change without prior notice. | |||||||||||

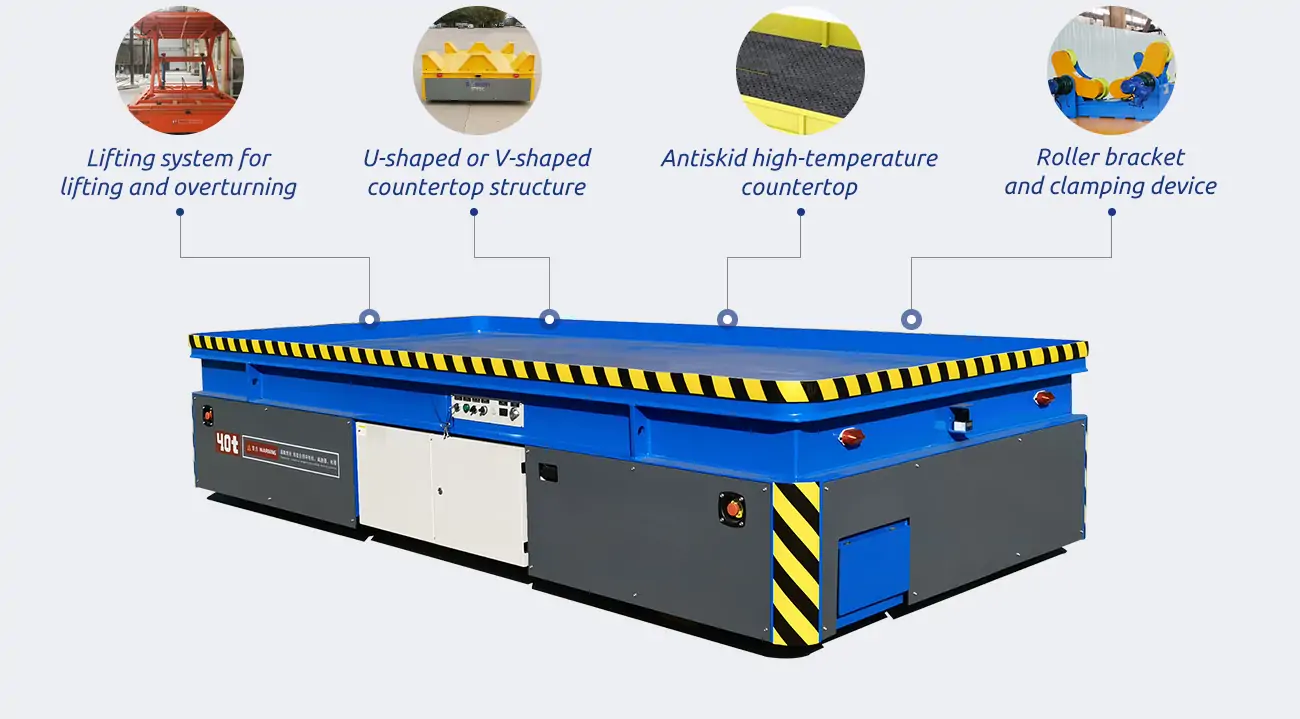

Характеристики

Heavy-duty transport

Capable of transporting 30-ton steel coils per unit, meeting the heavy-duty handling requirements of cold-rolling production lines and steel processing enterprises.

Hydraulic lift

Loading and unloading of steel coils with height adjustment to prevent damage caused by ground friction.

Agile movement

Hydraulic steering + omnidirectional steering enables 360-degree rotation on the spot and lateral movement, reducing requirements for working space.

Energy saving

Maintenance-free battery operation eliminates the need for frequent charging or replacement, resulting in low maintenance costs.

Safety Protection

Progressive acceleration, safety sensors, collision avoidance systems, and warning light strips provide quadruple protection to safeguard personnel and equipment.

Customised production

Standard components can be flexibly configured to suit enterprise scenarios, or professionally customised to address your specific requirements.

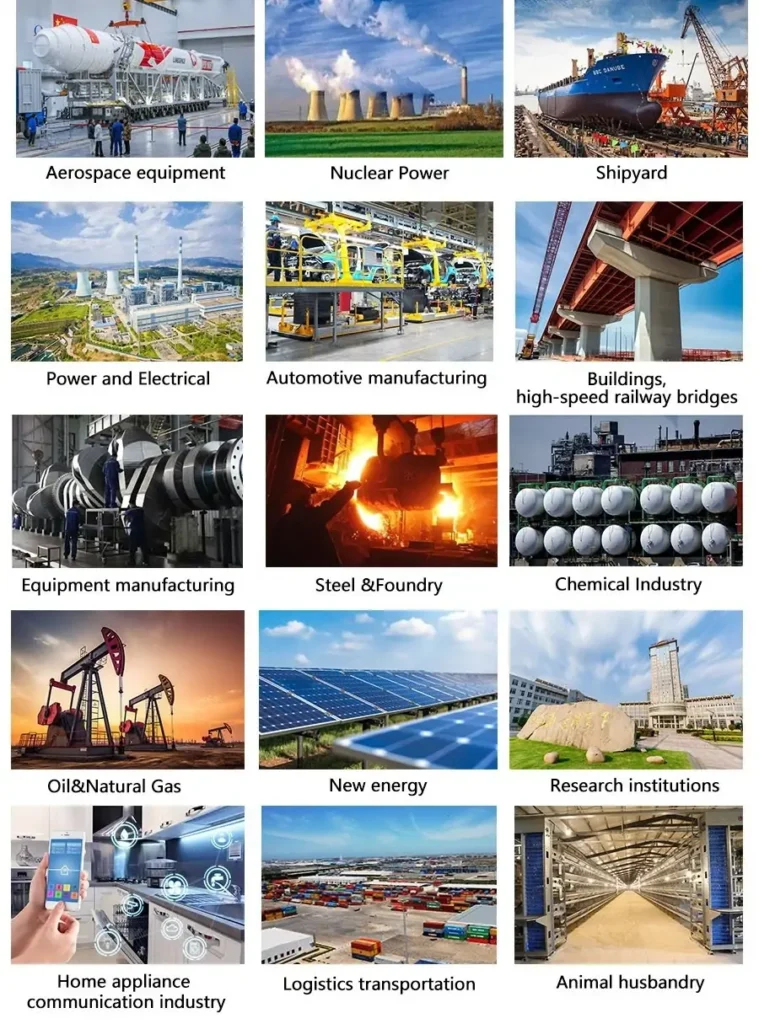

Приложение

As a core product within heavy-duty material handling equipment, the 30 Ton steel coil transfer cart not only possesses fundamental capabilities such as substantial load capacity, hydraulic lifting, and agile steering, but can also be custom-designed to meet the specific requirements of diverse industries. It demonstrates outstanding performance not only in the steel coil and chemical sectors but also finds varied applications across other industries:

Аэрокосмическая промышленность: For the precise handling of fuselage sections, wings, tail assemblies, and engines within the aerospace industry. Steel coil transfer carts may be equipped with laser obstacle avoidance systems and shock-absorbing platforms to ensure the safe transport of oversized aerospace structural components.

Metallurgy and Steel Industry: In steel mills and rolling mills, steel coils and billets weigh tens of tonnes. The 30-ton steel coil transfer cart, equipped with a hydraulic lifting saddle and reinforced coil support brackets, enables rapid loading and unloading of steel coils and billets, thereby reducing surface scratches and minimizing the occurrence of safety incidents.

Power and Energy Sector: When transporting turbine rotors, transformers, and cable reels, the 30-tonne steel coil transfer cart can be customised with fixed components and clamping platforms to minimise equipment movement and damage during conveyance.

Новая энергетическая промышленность: In lithium battery and photovoltaic panel manufacturing, precision equipment and raw materials are sensitive to impact. The 30t steel coil transfer cart can be customized with dust-proof enclosures and anti-static wheels, ensuring safe transportation of fragile and flammable components while reducing fire hazards.

Shipbuilding Industry: Handling ship sections, steel plates and propellers within the dockyard space. Equipped with omnidirectional wheels, the 30-tonne coil transport vehicle enables the safe movement of oversized hull components within confined spaces.

Rail Transit Industry: When handling train wheelsets, bogies, and track components, this steel coil transfer cart can be upgraded with an automatic track alignment device and hydraulic clamping system, enabling precise positioning and efficient assembly within railway workshops.

Cases Show

Steel Coil Transfer Cart Manufacturer

Henan Remarkable Intelligent Technology Co., Ltd was founded in 2019 and is located at No. 22, Xinchang North Line, Xiaodian Town, Hongqi District, Xinxiang City, Henan Province. It is a professional handling equipment company integrating R&D, design, manufacturing, sales, and after-sales service. It specializes in the production of various types and tonnages of handling equipment and their accessories, and provides professional R&D, design, and manufacturing of various non-standard and Электрические тележки, Rail transfer carts, Omnidirectional mobile transport carts, Battery transfer carts, Heavy load transport carts, AGV handling robots, and industrial trailers.

The Remarkable’s products comply with the JB/T6127-2010 machinery industry standard, have passed the ISO three-system certification (quality, environment, and occupational health), and the CE certification. It has obtained 19 national product patents successively.

Почему выбирают нас?

- Industry-Specific Expertise – We serve power generation, shipbuilding, construction, and aerospace sectors with tailored solutions for transformers, wind turbine components, prefabricated modules, and more.

- Fully Customized – From load capacity (1–500+ tons) to drive systems (electric, hybrid, or diesel), meet your exact requirements.

- Advanced Control Systems – Options include manual remote control, semi-automatic path planning, or fully automated navigation (AGV integration).

- Quality & Durability – Robust steel frames, high-torque steering modules, and CE, ISO-certified.

- Full Project Support – From initial consultation to after-sales service, our engineers provide lifetime technical assistance.

Похожие статьи

Индивидуальные интеллектуальные решения для транспортировки материалов

Чтобы индивидуальная тележка для перевозки грузов идеально соответствовала вашим потребностям, укажите следующие данные:

- Грузоподъемность: _____ тонн (1~500 тонн)

- Размер стола: _____ × _____ мм/м (например, 1500×3000)

- Варианты питания:

- ☐ Свинцово-кислотные ☐ Литий-ионные ☐ Другие: _____

- ☐ Кабель: _____V/_____A

- ☐ Стандартный 380 В/50 Гц/3-фазный

- Грузовые детали:

- Тип: _____ (например, рулоны стали, машины)

- Особые потребности: _____ (например, противоскользящие, антикоррозийные)

- Дополнительные функции:

- ☐ Аварийная остановка ☐ Датчики предотвращения столкновения

- ☐ Рельсовые направляющие ☐ Подъемный механизм ☐ Пульт дистанционного управления