We are a Chinese manufacturer specializing in custom-made electric transfer carts. Our product line encompasses a full range of carrinhos de transferência, including electric transfer carts, customized transfer carts, industrial transport carts, rail transfer carts, and heavy load AGVs. We understand that businesses require clear, practical guidance to fully leverage these high-efficiency devices. Today, I will share insights on the composition, efficient operation, and reliable maintenance techniques for heavy-load AGVs.

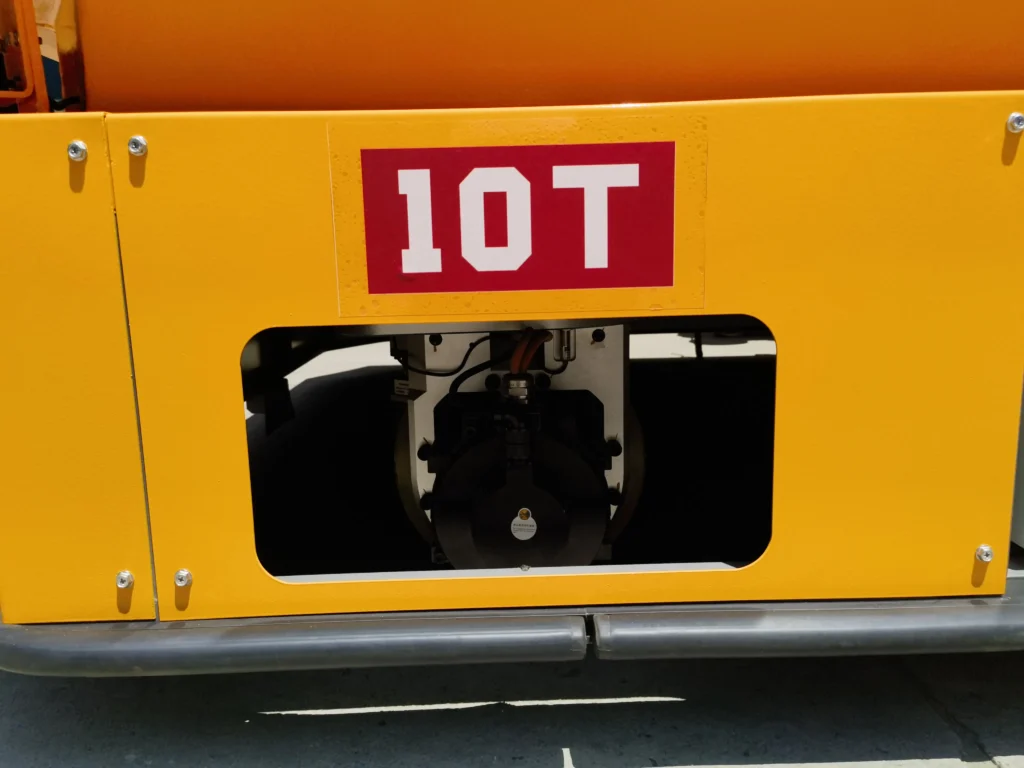

First, we should understand: What is AGV? What does AGV stand for? AGV stands for Automated Guided Vehicle, which can automatically perform material handling tasks. It can be remotely controlled, manually, or pre-programmed to execute specific transport missions. In manufacturing settings, people often ask: What is AGV in manufacturing? Manufacturing AGVs encompass various types designed for transporting different equipment. Heavy load AGVs are specifically engineered heavy-duty transfer carts for moving large machinery, typically handling loads ranging from 5 to 100 tons. These heavy-duty AGVs require reinforced chassis and frames, powerful motors, and advanced navigation systems paired with custom attachments like lifting frames to ensure safe and stable transportation of heavy equipment.

Structure of Heavy Load AGV

Our heavy-duty AGVs are built with reinforced, durable components to ensure stable and reliable operation. Below are the common structural elements.

- Frame: Constructed from high-strength steel or alloy materials, it remains free from deformation or damage when handling loads up to 100 tons.

- Power: Our heavy-duty AGVs are typically equipped with dual or quad high-torque motors, delivering ample power to handle inclines with ease.

- Tires: We utilize explosion-proof rubber/polyurethane wheels, each independently controllable for 360-degree rotation and individual drive, enabling agile maneuvering.

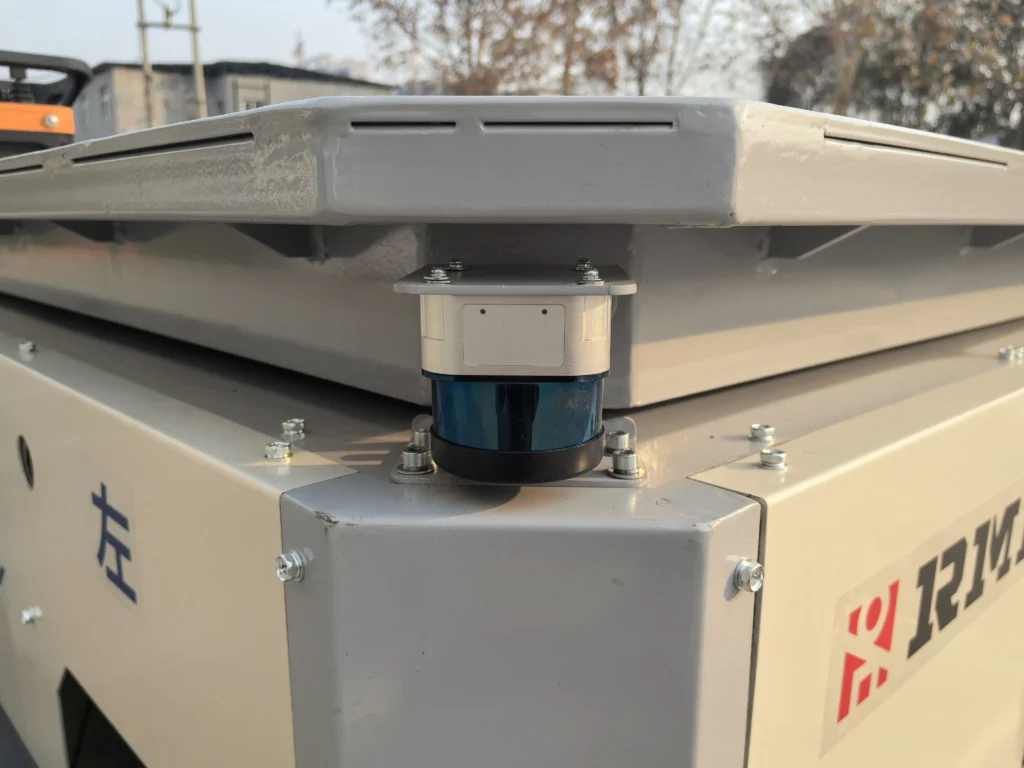

- Navigation System: Multiple modes available, including wired/wireless handheld remote control; fixed magnetic strip/magnetic stud guidance; laser navigation; and real-time visual AI system monitoring.

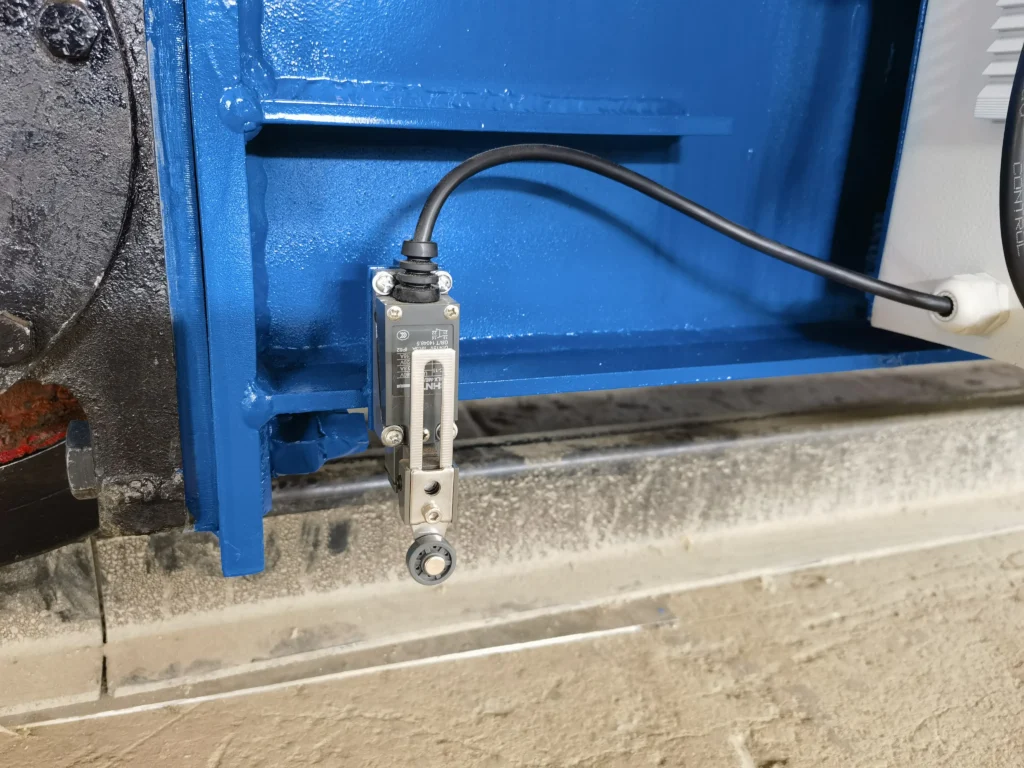

- Safety System: Equipped with emergency stop buttons, obstacle detection sensors, warning lights, and alarms to alert personnel of AGV operational status.

- Custom Workpieces: Customizable lifting platforms, transport pallets, V-shaped fixtures, and other fixed auxiliary handling equipment.

The above outlines the common structural components of Heavy Load AGVs. For detailed customization requirements, our professional engineers will provide tailored solutions based on your needs.

How to Use a Heavy Load AGV Effectively

Proper operation of your Heavy Load AGV not only reduces malfunctions but also extends its service life.

Step 1:

- Plan its route and operating mode, such as handle control or magnetic strip guidance.

- Schedule its operating times to avoid overlapping with other tasks, ensuring optimal efficiency.

Step 2:

- Pre-inspect the Heavy Load AGV’s operational status, including battery charge level, navigation system cleanliness, and tire/ground wear.

- Conduct an empty run to verify all functions operate normally, minimizing safety incidents.

- Perform a fixed-load check to ensure cargo remains secure and won’t shift or fall during transport.

Step 3:

- Operators must be trained before the operation.

- Operators must control the Heavy Load AGV via remote or system commands—manual pushing is strictly prohibited;

- Monitor operational status in real-time and immediately halt operations upon detecting abnormalities.

The above outlines efficient Heavy Load AGV operation methods. Next, we explore how to extend its service life.

Maintenance of Heavy Load AGV

Proper maintenance prolongs the Heavy Load AGV’s lifespan and ensures stable performance.

Daily Maintenance

- Clean equipment: Wipe down the chassis, sensors, and control panel to remove dust and grease that may interfere with navigation.

- Inspect wheel assemblies: Replace rubber tires immediately if cracks appear or tread depth falls below 3 mm. Lubricate steel axles regularly to prevent rust.

- Test safety functions: Press the emergency stop button and trigger obstacle sensors to confirm proper operation.

Weekly Maintenance

- Inspect Load Frame: Check for dents, paint peeling, or other signs of stress damage. Contact us for repairs immediately if issues are found. Do not use until repaired.

- Maintain Batteries: Clean battery terminals to prevent corrosion. Top up lead-acid batteries with distilled water (never use tap water).

- Lubricate Moving Parts: Apply industrial grease to the lifting mechanism, motor bearings, and steering joints.

Monthly Maintenance

- Navigation Calibration: After prolonged use, navigation sensors may drift. Re-align the path using the device’s built-in calibration tool.

- Electrical Inspection: Check control system wiring for loose connections or wire wear. Replace damaged components immediately (electrical issues are the primary cause of AGV failures).

- Load Capacity Testing: Test with 50% of the rated load to ensure stable performance of the lifting mechanism and chassis.

Professional Maintenance

- Our technicians will conduct comprehensive on-site inspections:

- Assess motor and battery degradation.

- Update control system software to the latest version (enhancing performance and safety).

- Proactively address potential issues (e.g., replacing aged motor bearings).

These maintenance steps will significantly extend your Heavy Load AGV’s lifespan and ensure stable operation.

Conclusion:

This guide provides clear guidance for safely operating your Heavy Load AGV. As a manufacturer specializing in customized Heavy Load AGVs, we not only supply equipment but also offer tailored solutions.

For further inquiries—such as “AGV applications in my specific manufacturing sector” or “selecting the right heavy-duty AGV”—feel free to contact us anytime. We are committed to optimizing your material handling processes with reliable, customized heavy-load AGV systems.